- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on microwave drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on microwave drying

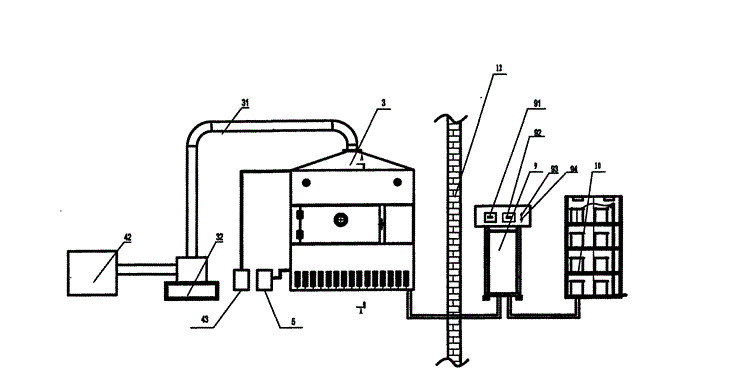

2018-10-25 14:11:06Based on the test results and years of production experience, the microwave output power listed in the microwave drying reference list of some commonly used tree species and sawn timber specifications is proposed. For a channel microwave dryer like Wuxi Furniture Factory II, which consists of four two resonant cavities in series, the first three (1-3) can be of medium power. Begin to gradually increase to the maximum upper limit, the last (fourth) take the minimum power (lower limit), to avoid serious mismatch, damage pipe 2.

The results showed that the quality index of wood microwave drying could be added with carbonization index on the basis of convective drying quality index (average final moisture content, drying uniformity, moisture content gradient, stress deviation, visible defects such as cracking, bending, etc.). There are 385 samples in this experiment, only 9 of them are carbonized, accounting for 2.3%. If the moisture content gradient on the thickness of the wood according to the above drying criteria, the result of this test is satisfactory.

It reflects the obvious law that the water content of surface layer is higher than that of core layer (see Table 1).This is the characteristic of microwave drying different from convection drying. The distribution of final moisture content of 01.2.6 Xin Lan song 48 was uniform along the length of test material.

For the specimen with a length of 1 meter or more, the water content at both ends does not increase the shape of the stress specimen after a period of equilibrium. In most cases, the tooth bends outward, forming a negative stress deviation according to formula.

The reason is that the moisture content of the wood surface is higher than that of the core layer, and the residual tensile deformation of the core layer occurs first. This is the national standard that microwave drying is different from convective drying and there is no stress deviation in China. According to the Soviet standard, the deviation should not be allowed. According to the test results in Table 2, the average stress deviation of half of the materials is more than 2%. It is concluded that the sawing method and numerical value of microwave drying test pieces should be further studied to keep the natural color of wood. This is another characteristic of microwave drying. When wood is dried by tunnel microwave dryer, which is inferior to convective high temperature drying (including superheated steam drying), it is easy to bend because of uneven drying and anisotropy. Therefore, it is necessary to study and improve the equipment and technology.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply