- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying kinetics and energy consumption analysis of cotton stalk

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying kinetics and energy consumption analysis of cotton stalk

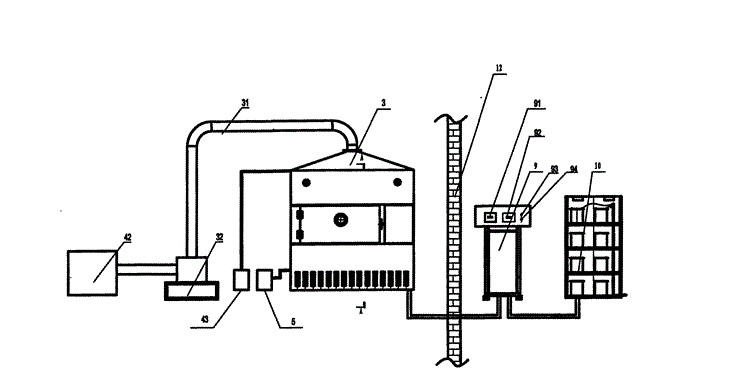

2018-10-31 17:04:36Abstract: In order to study the effect of loading on the drying time, drying rate, drying efficiency and unit energy consumption during microwave drying of cotton stalks, the experiment used microwave drying equipment with a microwave frequency of 2 450 MHz and an output of 1 kW. The amount of cotton stalks ranging from 34 to 200 g is dried.

The results show that: the microwave drying equipment is in the deceleration phase after a short speed increase; the dry data is nonlinearly fitted by 7 common thin layer drying models, and the coefficient, root mean square error and dispersion are determined by comparison. Sum of squares, the Midilli model was found to be the optimal model for microwave drying of cotton stalks. The drying coefficient decreased with the increase of loading. When the loading increased from 34 g to 200 g, the drying time increased from 10 min. By 20 min; the effective diffusion coefficient of water in the cotton stalk decreases with the increase of the loading, and the average value is between 1.8078×10-8~4.1997×10-8 m2/s, and the average is obtained based on the Arrhenius equation. The activation energy is 4.82 W/g; when the loading is 34-200 g, the microwave drying efficiency can be improved by increasing the loading (7.52% to 19.78%), and the unit energy consumption of microwave drying (12.49-35.90 MJ/kg) is reduced. . The research results provide reference for the drying and industrial production of cotton stalks.

Key words: cotton stalk microwave drying; kinetics; disintegration cotton stalk; drying efficiency; energy consumption

Introduction

Crop straw is a kind of renewable resource. The main components are similar to some broad-leaf wood. The use of straw instead of wood to produce wood-based panel materials has a positive effect on saving wood resources and improving straw utilization efficiency. Cotton stalks have semi-lignifying properties and high cellulose content, which is a good biomass resource for replacing wood. The cotton stalk recombinant material is softened, crushed and combed into a transversely unbroken, longitudinally interlaced curtain-like mesh straw bundle under conditions that do not substantially destroy the longitudinal strength of the straw, dried, sized, and slab And hot pressing and other processes. The dry basis moisture content of cotton stalks usually exceeds after softening treatment

100%, and need to be reduced to 6% before sizing, in order to facilitate the sizing and subsequent pressing process, so the drying process of cotton stalk after decontamination is an important process, which will directly affect the production efficiency and performance of the restructured material. .

There are few reports on the drying of crop straws, especially the drying of cotton stalks after disintegration. At present, the drying of straw mainly adopts the natural air drying method, the drying is not thorough, and the drying efficiency is low, which limits the demand for continuous and industrial production. In recent years, hot air drying has been widely used in the drying of grain, fruits and vegetables, and wood. Dry air drying can improve drying efficiency. However, excessive hot air drying tends to cause hardening of the material skin, which affects the drying rate. Compared with traditional hot air drying and infrared drying, microwave drying is a more rapid, uniform and efficient drying method. Microwave heating can simultaneously heat the inside and outside of the medium without heat conduction. The temperature difference between the inside and outside of the material is small and the heating is uniform, so the heating speed very fast.

By studying the mathematical models of various drying mechanisms, it is possible to better optimize the drying process and design more efficient drying equipment. Therefore, this study explored the microwave drying characteristics of cotton stalks by studying the kinetic model, energy consumption and drying efficiency of the mass transfer during the microwave drying process of cotton stalks, in order to select the drying process parameters and design and development of drying equipment. Provide a theoretical basis.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply