- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Characteristics and influencing factors of microwave drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Characteristics and influencing factors of microwave drying

2018-11-02 16:46:07

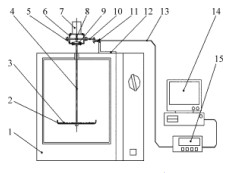

In the early stage of drying, the moisture content of materials is high, the ability of absorbing microwave energy is strong, the temperature rises rapidly, and the material temperature tends to be stable, so most of the water loss process of wheat is in the stage of constant-speed drying. In hot air drying and other radiation heating drying, the whole drying process can be divided into accelerated drying stage, constant drying stage and decelerated drying stage. Most of the water loss process of wheat is in a very slow deceleration stage.

This is because microwave has longer wavelength and better penetration than other electromagnetic waves used for radiation heating, such as infrared radiation. It can penetrate most non-metallic materials to a considerable depth. The drying materials are heated in the same table. The temperature gradient and humidity gradient in the materials are also consistent. The water migration speed in the materials is also consistent with the surface water. The evaporation rate kept constant for a long time.

1) The effect of microwave drying equipment on wheat quality is significant. The germination rate of wheat grain is sensitive to drying temperature and can be used as an index of wheat thermal damage. SDS sedimentation value is sensitive to drying power response and can show the trend of quality change. It can be used as an indicator of wheat quality change.

2) Different from other drying methods, the whole process of wheat microwave drying can be divided into two stages: constant-speed drying and slow-speed drying. Most of the drying process is in the constant-speed stage. Therefore, for wheat microwave drying, the method of subsection drying can be adopted, that is, different heating measures can be adopted at different drying stages.

3) Drying power, wind speed and drying laying thickness are the main technical parameters of wheat microwave drying. They directly affect the drying time, quality and energy consumption of wheat after drying, especially the wind speed. The results show that when the drying power of wheat microwave drying is 0.2 W/g, the laying thickness is 2 cm and the wind speed is 45 m/min, the seed value, edible value and storage convenience of wheat drying can be ensured, and the energy consumption is low.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply