- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Drying experiment of potato chips

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Drying experiment of potato chips

2018-11-06 17:06:39Materials and instruments

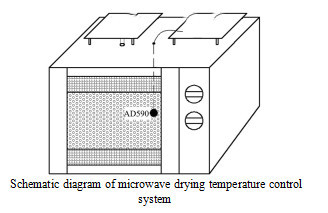

Microwave drying test device: electrothermal blower box, JH423 - 4 electronic balance, microwave drying equipment

Method of determination

The initial moisture content is determined by national standards. Before the drying test, the potatoes were cleaned and sliced into thick filter paper to absorb the surface moisture according to the need of the test, and then evenly spread into a layer on the container as required. During the drying process, the material weight was measured regularly until the moisture content of the wet base was safely stored around the water content.

Results and analysis

Effect of slice thickness on drying characteristics of drying characteristics

The drying process can be divided into three stages: accelerated drying stage, constant drying stage and decelerated drying stage. Therefore, under the same drying conditions and a certain time, with the increase of slice thickness, the water content of potatoes increased slightly. It may be due to the increase of the thickness of the slices, the internal water migration to the outer layer needs a process, and the microwave attenuation in the process of penetration.

The calculation of microwave drying potato comprehensive optimization, pre launch power, transmission power, time of early late after drying of various indicators, although an objective function is optimized, but only for the objective function, however, microwave drying, should be considered the influence of these four objectives Therefore, it is necessary to carry out comprehensive optimization of the above three factors, and then find the best combination of microwave drying, meet the four objective function.

This is a multi-objective non-linear optimization problem. The evaluation function method is used to transform it into a single-objective non-linear optimization problem. The higher the quality of potatoes, the water recovery ratio and the precipitation rate per unit time, the better the unit power consumption. At the same time, the four objective functions have different dimensions. Extremum problem of linear type efficacy coefficient method is to compute the regression equations of the standardization process to find the optimal value of the 678. After comprehensive optimization, the initial transmitting power and the late transmitting power are all 90 2:; <

That is to say, the unit mass emission power is 90 2:; < < > the comprehensive index of potato microwave drying is better.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply