- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on microwave drying characteristics of Pinus massoniana wood

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on microwave drying characteristics of Pinus massoniana wood

2018-11-12 11:46:08

Abstract : The variation of microwave drying speed, temperature gradient and water content gradient of Pinus massoniana wood with time was studied. The experimental results show that the microwave continuous drying process is obviously divided into three stages: acceleration section, constant velocity section and deceleration section. The constant velocity section accounts for the largest proportion in the whole drying process.

During the microwave drying process, the temperature change is roughly divided into three stages: initial temperature rise, isothermal and late temperature rise. The temperature distribution in the initial temperature rise and isothermal stages is relatively uniform, and the temperature difference in the wood in the late heating stage gradually increases. During the microwave drying process, the initial moisture content gradient of the wood was not increased over the entire cross section, but was evenly homogenized, and even the moisture content of the wood surface increased.

Key words: forestry engineering; masson pine; microwave drying equipment; drying characteristics; water content gradient

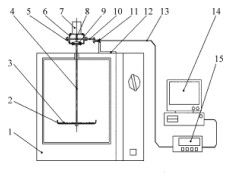

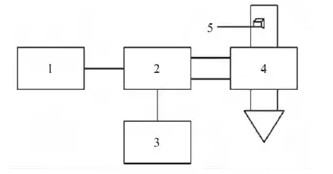

Wood microwave drying is a relatively new drying technology, which has the advantages of fast drying speed and environmental friendliness. Chinese scientists and technicians have made many meaningful explorations and attempts in the field of wood microwave drying. Their research mainly focuses on the dielectric properties of wood under the microwave drying equipment, process and microwave electromagnetic field , in wood microwave There are few studies on the theory of dry heat and mass transfer. The authors studied the drying speed, temperature field and water content field of Pinus massoniana plate under microwave heating conditions. The report is as follows, which provides a theoretical basis for the development of wood microwave drying process.

From the above experiments, the following conclusions can be drawn:

1 Microwave continuous drying process can be obviously divided into three stages: acceleration section, constant velocity section and deceleration section, in which the constant velocity section accounts for a large proportion in the whole drying process.

2 The temperature change of the microwave drying process is roughly divided into three stages: heating and heating section, isothermal section and late heating section. In the heating and isothermal stages, the temperature distribution in the wood is relatively uniform, and the temperature difference increases during the late heating stage.

3 In the microwave drying process, the original moisture content gradient in the wood is not increased over the entire cross section, but is evenified, and even the moisture content of the wood surface is increased.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply