- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying methods on properties of lotus root starch

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying methods on properties of lotus root starch

2018-11-14 11:45:18

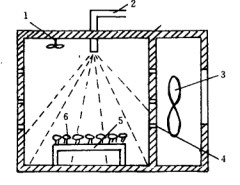

Absrtact: The effects of four drying methods, hot air drying, microwave drying equipment, vacuum microwave drying and infrared drying, on the drying time, brightness, microstructure, crystal type, viscosity, condensation stability, freeze-thaw stability and transparency of lotus root starch were studied. The results showed that the X-ray diffraction patterns of Lotus Root Starch Treated by hot air drying, microwave drying, vacuum microwave drying and infrared drying were identical, and the crystal types were B-type.

In hot air drying and infrared drying, starch granules have irregular shape, rough surface, obvious pits, serious agglomeration and cracks among granules, and poor appearance quality. In microwave drying and vacuum microwave drying, the whole structure of large granules is ellipsoid, small granules are spherical, no agglomeration, vacuum microwave drying lotus root starch granules. Complete, clear outline and smooth surface.

Four drying methods for lotus root starch, vacuum microwave drying starch brightness, condensation stability are the best, transparency is the lowest, and microwave drying time is the shortest, freeze-thaw stability is the best. Comprehensive analysis shows that vacuum microwave drying is superior to the other three methods, and can be applied to the industrial production of lotus root starch and starch products.

Key words: lotus root microwave drying, lotus root starch, different drying methods, characteristics

Lotus root (Nelumbonucifera Gaertn) is a perennial plant of the water lily family. It has been cultivated for more than 3000 years in China. Lotus root is widely cultivated in China. Lotus root starch is the main nutritional ingredient with a content of 10% to 20%. Lotus root resources are abundant in China. Lotus root can be processed into starch, which can be used as an important raw material and auxiliary material in food processing industry. It has great resource advantages and development prospects.

Researches on lotus root starch have also been reported at home and abroad. Tian Cuihua and others focused on the study of the crystal, granule, aging and gelatinization characteristics of lotus root starch. Song Zhe studied the fine structure, digestibility and water molecule movement of lotus root starch in different periods. Qian Wenwen and others studied the granular shape of lotus root starch of different varieties. In order to investigate the effect of hydrophilic colloids on starch properties, Liu Min et al. studied the gelatinization, rheology, texture and microstructural changes of lotus root starch with different dosages of xanthan gum and konjac gum.

Chen Qiaoli et al explored the effect of high static pressure on the physicochemical properties of lotus root starch. Tujing et al. used near infrared spectroscopy to nondestructively detect the starch content of lotus root. Deng Qing et al. used lotus root starch as raw material, cooking, texture and sensory as indicators, investigated the effect of lotus root starch on the quality of vermicelli. Li Xiteng et et et al. made enzymatic preparation of lotus root resistance. Study on starch technology. At present, there is no report on the comparison of the characteristics of lotus root starch in different drying methods.

In this paper, lotus root starch was treated by four drying methods: hot air drying, microwave drying, infrared drying and vacuum microwave drying. The drying time, particle morphology, crystalline type, color, viscosity, freeze-thaw property, transparency and condensation of lotus root starch were compared to extract lotus root starch and starch products. For theoretical basis.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply