- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Drying Characteristics of Peony Seeds

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Drying Characteristics of Peony Seeds

2018-11-19 15:15:29

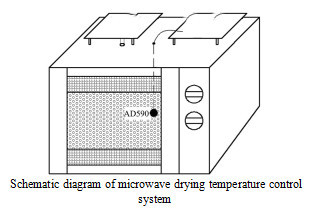

Abstract: In order to explore a method that can quickly dry peony seeds and dry them, the method is to prolong the storage time and ensure the quality of oil extraction. The peony seeds are tested by microwave drying equipment. The heating time, intermittent time and material layer thickness of microwave drying were selected as experimental factors. The microwave drying characteristics of peony seeds were studied. The drying rate, shelling rate and ripening rate of peony seeds were used as evaluation indexes. The optimum process parameters of peony seed microwave drying were obtained by the integrated balance method.

The results showed that the dehydration process of peony seeds was mainly in the constant speed stage. Different microwave drying parameters had different effects on the microwave drying characteristics of peony seeds. When the drying time was 20 s, the rest time was 60 s, and the material layer thickness was 2 layers. It can obtain a faster drying rate under the premise of ensuring the quality of peony seeds.

Key words: peony seed microwave drying; intermittent time; orthogonal test

introduction

Peony is the national flower of China. Peony seed is the essence of peony. It is a nut protected by double shells and seed shells. Peony seed oil can lower blood pressure and lower blood fat, and has high medicinal and economic value. Peony seeds must be dried before storage to prevent mildew and deterioration and subsequent deep processing. The traditional peony seed drying method uses drying method, the drying period is long, it is easy to mold and needs a large drying space, which greatly limits the development of the peony industry. Therefore, it is urgent to find a better method for drying peony seeds.

At present, the commonly used drying methods mainly include hot air drying, far infrared drying, vacuum freeze drying and microwave drying. Among them, hot air drying has problems such as long drying time, low drying efficiency and low energy utilization rate; far infrared drying and vacuum freeze drying have good drying quality, but high investment cost; microwave drying and drying rate is fast, thermal effect is high, and can be shorter The water content is controlled within a safe storage period, the quality is good after drying, and it can be sterilized.

Foreign countries have started research on microwave drying agricultural and sideline products more than 20 years ago. In recent years, there have been more and more reports on microwave drying in coriander, ginkgo and longan, and some have been successfully applied and achieved remarkable economics. benefit. However, the microwave drying process parameter setting is unreasonable, and it is easy to cause the peony seed to burst and make the kernel mature. The research objective of this experiment is to find a technical parameter for microwave drying which can quickly dry peony seeds and have low shelling rate and ripening rate, and provide basis for the research and design of industrial drying equipment. Therefore, this paper conducted a batch microwave drying test on peony seeds.

Estudio sobre las características de secado por microondas de semillas de peonía

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply