- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of Different Drying Methods on the Quality of Golden Peony Oolong Tea

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of Different Drying Methods on the Quality of Golden Peony Oolong Tea

2018-11-20 15:54:43

Abstract: This paper studied the effects of traditional drying, double drying and microwave drying equipment on the internal components and aroma of Golden Peony Oolong Tea. The indicators of tea polyphenols, amino acids and soluble sugars were determined. Finally, compared with traditional drying, the microwave polyphenols and golden peony oolong tea had reduced polyphenols and soluble sugar content and increased amino acid content.

After extracting the aroma by the SDE method, the aroma components analyzed by GC-MS showed that the aroma components of the microwave-dried tea were less than the traditional dry (41 and 48, respectively), and the main aroma component of the golden peony oolong tea was the orange flower. Alcohol, methyl linolenate, α-farnesene, hydrazine, 5-hydroxycaprolactone, β-phenylethyl alcohol, palmitic acid, phytol alcohol, phenylacetaldehyde, cis-jasmone. The neroliol is the highest aroma component, accounting for 39.72%, 35.68%, and 43.9% of the total aroma extract, respectively. The traditional drying method is more conducive to the aroma quality characteristics of the golden peony oolong tea, but the microwave drying method is more time-saving and labor-saving and the overall quality is better.

Key words: microwave drying golden peony oolong tea; tea polyphenols; aroma components

The Golden Peony was developed by the Tea Research Institute of the Fujian Academy of Agricultural Sciences from 1978 to 2002 with Tieguanyin as the female parent and Huangqi as the male parent. In 2001, it was awarded the “Ninth Five-Year Plan” for the first-class excellent germplasm of crops. In 2003, the Fujian Provincial Crop Variety Approval Committee was approved as a provincial-level variety. In 2010, it passed the national-level variety appraisal. The variety is shrub type, middle leaf type, early seed. The bud leaves have strong fertility, strong tenderness, and the first bud and three leaves are in the early April. The variety of this variety is high, the quality of the oolong tea is excellent, the rope is tight and firm, the aroma is long and fragrant, the taste is mellow and sweet, the "rhyme" taste is obvious, the quality characteristics of Tieguanyin are high, and the production rate is extremely high. The cutting propagation is strong, the survival rate is high, and the drought resistance, cold resistance and adaptability are strong.

Drying is the last step in tea processing. Tea leaves lose moisture through drying, develops aroma, fixes quality, and is easy to store. During the drying process, the cracking and isomerization of some insoluble substances in the tea leaves have a good effect on improving the taste and aroma. Microwave drying is widely used in food processing, such as dry ginger, eucalyptus tea and spinach. Microwave drying is more studied in terms of differences in biochemical components and aroma components than conventional drying.

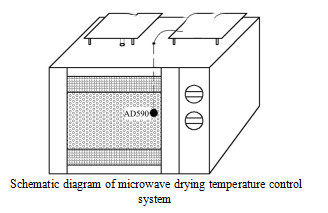

The principle of microwave drying is that the microwave generator radiates microwaves onto the dried tea leaves. When the microwaves are injected into the interior of the tea leaves, the polar molecules such as moisture in the tea leaves are induced to rotate synchronously with the frequency of the microwaves, so that the tea leaves instantaneously generate frictional heat. It causes the surface and interior of the tea to heat up at the same time, so that a large amount of water molecules escape from the tea leaves and are evaporated to achieve the effect of drying the tea leaves.

Compared with other drying technologies, microwave drying has the advantages of uniform heating, short time, high thermal efficiency, no environmental heating, easy automatic control and continuous production, and has broad application prospects in tea processing. In this paper, the effects of different drying methods on the contents and aroma components of Golden Peony Oolong Tea were studied. By comparing the comprehensive quality of different drying methods, the drying methods with good performance were screened, which had positive significance for promoting different drying methods.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply