- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Coupling drying characteristics and kinetic model of yam microwave hot air

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Coupling drying characteristics and kinetic model of yam microwave hot air

2018-11-21 14:35:36

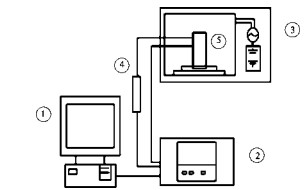

Abstract: In order to explore the coupling characteristics of yam microwave hot air, microwave drying equipment was used to study the effects of different slice thickness, hot air temperature, hot air rate and microwave power density on the drying characteristics and effective diffusion coefficient of yam, and a dry kinetic model was established.

The results show that: yam microwave drying the process is divided into two stages: acceleration and deceleration according to the change of dry basis moisture content. There is no obvious constant speed stage; the effective diffusion coefficient of yam is 0.879 1×10-6~8.245 8×10-6 m2/s, The value is proportional to the slice thickness, hot air temperature and microwave power density, and decreases first and then increases with the increase of the hot air rate; compared with the hot air rate and the hot air temperature, the slice thickness and the microwave power density have an effective diffusion coefficient for water. The impact is even more pronounced.

By fitting 9 common drying models, it is shown that the two-term exponential model has the largest R2 average, and the mean χ2 average and root mean square error are the smallest, which are 0.998 0, 0.000 2 and 0.014 7 respectively.

The predicted values of the Two-term exponential model fit well with the experimental values under the same experimental conditions, which indicates that the model is suitable for predicting the change of moisture content in the microwave hot-air coupled drying process of yam. The results of this study can provide a theoretical basis for the application of microwave hot air coupled drying technology to the drying of yam and other agricultural products.

Key words: yam; microwave hot air coupling; drying characteristics

Yam is a tuber of the genus Dioscorea zingiberensis, also known as potato, sweet potato, earth potato, hawthorn, maize, etc. It is one of the traditional food and food homologous foods in China. In addition to a large amount of protein, vitamins and mucopolysaccharides, yam is rich in various functional ingredients such as saponins, choline and allantoin, and has high edible, medicinal and health care value. However, the fresh yam has a high water content, while the fragile texture is vulnerable to external damage, and it is difficult to store at a normal temperature for long-term storage and long-distance transportation. In order to extend the shelf life of yam, it is often treated by a dehydration drying process.

In recent years, many researchers have studied the drying technology of yam. Song Xiaoyong used the far-infrared-assisted heat pump drying method to study the effect of the method on the quality of mountain tablets. It was found that the far-infrared-assisted heat pump drying method solves the surface hardening, local overheating, color irregularity, etc. that often occur in the traditional drying process of mountain tablets. The phenomenon has a significant effect. Li Li et al. studied the drying characteristics and mathematical model of yam heat pump. The results show that the heat pump drying characteristics of yam accord with the Page equation. The mathematical model can be used to predict the change of water loss rate during the drying process of yam heat pump.

Microwave hot air combined drying technology mainly includes two ways: one is to connect microwave and hot air in series, that is, microwave or hot air drying in stages to achieve the purpose of drying; the other is to connect microwave and hot air in parallel, also called coupling drying. That is, simultaneous microwave and hot air drying. During the drying process, the water in the material is heated, migrated and evaporated under the combined action of four physical fields: electric field, magnetic field, temperature field and velocity field. The heat transfer and mass transfer directions in the microwave hot air coupling drying process are consistent, which can greatly shorten the drying time, significantly improve the drying efficiency, reduce the energy consumption, and at the same time, retain the original nutrient elements of the dry materials to the maximum extent and improve the drying quality.

In this study, the yam was used as the object, and the microwave hot air coupled drying technology was used to study the coupling characteristics of yam microwave hot air and the change of water during drying. The effects of different slice thickness, hot air temperature, hot air rate and microwave power density on the drying characteristics of yam were discussed. The kinetic model of yam microwave hot air coupled drying was established to provide theoretical basis and technical support for the application of yam drying and microwave hot air coupling drying technology.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply