- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> mprovement of drying process of Weikang capsule

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

mprovement of drying process of Weikang capsule

2018-11-21 17:07:38

Key words: Weikang capsule; improvement of drying process; ratio of decoction of extracting tablets; microwave drying equipment

Weikang Capsule is a self-made preparation in our hospital. It consists of a variety of medicinal materials such as Astragalus, Suanzaoren, Polygala, Ginger Pinellia, Acacia, Shouwu, Zhigancao, etc. The effect is Buzhongyiqi, nourishing blood and promoting blood circulation. Indications of spleen and stomach weakness or heart and spleen caused by stomach cramps pain, full of discomfort, palpitations, shortness of breath, insomnia and other symptoms. The microwave drying of Weikang Capsule is dry in the hot air circulation drying room, the drying period is long, and the quality of the product after drying is not high.

After purchasing vacuum microwave equipment in our hospital, we want to improve the drying process by vacuum microwave method. However, due to the excessive amount of jaundice in the prescription, the dried extract contains more saponins, which makes it easy to foam during vacuum microwave drying. As a result, the drying operation cannot be performed or even the overflow of the extract is lost.

By consulting the literature, a part of the jujube kernel meal in the prescription is mixed with the extract to change the properties of the dried material, and then dried in a box vacuum microwave drying to examine the ratio of the extract of the tablet, the concentration ratio, the drying time and the temperature. And other factors to get the best drying process.

In this experiment, the ratio of the extract of the decoction piece and the relative density have a significant effect on the quality of the final dried product, because the ratio of the extract of the decoction piece is too high, which may cause the material to be “yin and yang” due to unevenness (some parts have been dried, there are The part is not dry yet. If it is too low, the amount of the extract will be too large, and the material will overflow. If the relative density of the extract is too high, the loss rate of the extract will be too large during the concentration process of the sandwich pot, and the mixed material will be caused. Uneven, too low will cause the vacuum microwave drying cycle to be too long. Through the above test, it is reasonable to set the ratio of the extract of the wafer to 1:2 and the relative density of the extract to 1.2. The material after vacuum microwave drying is very hygroscopic, and needs to be sealed and stored in the granulation process within 2 hours after pulverization.

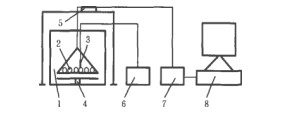

The box type microwave vacuum dryer used in this experiment is a new type of vacuum microwave application equipment that is intelligently controlled. When the equipment is running, such as combustion occurs in the cavity, it is strictly forbidden to inject gas into the cavity. deal with. When loading materials, the load should not be overloaded, and the weight of the materials in each tray should be equal to avoid damage to the rotating motor due to uneven force.

The water evaporated from the material during drying will condense and collect at the bottom of the drying chamber. At this time, the gas should be shut off and the equipment should be turned off to allow the condensed water to drain out of the equipment before drying. The device can only display the current drying temperature during operation, and can not display the moisture of the dry material online, which is an aspect that such equipment needs to be improved in the future.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply