- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying methods on quality and antioxidant activity of apricot meat powder

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying methods on quality and antioxidant activity of apricot meat powder

2018-11-30 14:05:17

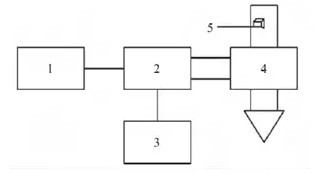

Absrtact: Pure natural apricot meat powder was prepared by microwave drying equipment, hot air drying, microwave vacuum drying and microwave convection drying. The effects of drying methods on nutrient composition, physical properties, sensory quality and antioxidant ability of apricot meat powder were compared.

Key words: apricot meat microwave drying; hot air drying; microwave vacuum drying; microwave convective drying; quality; antioxidant capacity

Apricot is a plum plant of Rosaceae, originated in Xinjiang, China. It has been cultivated for more than 3000 years. Apricot fruits contain a large number of phytochemicals, such as polyphenols, carotenoids and vitamins. These substances make them not only delicious, sweet and sour, pleasant flavor, but also have certain health effects on cancer and chronic diseases, which are deeply loved by people.

However, apricots are concentrated in the production season, easy to rot, can't stand storage and are difficult to keep fresh. They can only be stored for 3-7 days at room temperature. In order to prolong the storage period, many methods have been adopted, such as processing fresh apricots into preserved apricots, dried apricots and canned apricots, which are suitable for long-term storage; in addition, apricots have been established in China. The production line of pulp and apricot beverage is still very limited. 40%-50% fresh apricot still needs to be processed into dried apricot products in the producing area.

Natural air drying is the most commonly used method to produce dried apricot products at present, but it has the shortcomings of unsanitary and poor product quality. In general, low concentration sulfur fumigation in air drying is the most commonly used pretreatment method. This will cause sulfur residue in dried apricot products, which is contrary to the current market requirements for non-sulfur dried apricot products, so vigorously develop apricot. Deep processing technology is an important way to solve this problem.

Fruit and vegetable powder is a kind of powdered product made from fresh fruits and vegetables by dry or wet method. Because of its rich nutrition, delicious, easy storage, easy to carry, easy to mix and use, it has been favored by scholars at home and abroad. At present, the research on fruit and vegetable powder mainly includes jujube powder, purple potato powder, snow lotus powder, pumpkin powder, kiwifruit powder, pitaya powder and Western Blue pollen, etc. The research on apricot meat powder is less.

All kinds of methods have their advantages and disadvantages. It is very important to select suitable drying technology for the quality characteristics of fruit and vegetable powder. However, there is no report on the microwave combined drying technology of apricot meat powder.

In this study, four drying methods, microwave drying, hot air drying, microwave vacuum drying and microwave convection drying, were used to prepare apricot meat powder. The effects of drying methods on the nutrient composition, physical properties and antioxidant capacity of apricot meat powder were investigated in order to provide theory for the preparation of high-quality pure natural apricot meat powder products. Basis.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply