- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Heat and mass transfer analysis of apple slices during microwave drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Heat and mass transfer analysis of apple slices during microwave drying

2018-12-13 16:49:09

ABSTRACT: In the process of microwave drying apple slices, the quality and temperature of the samples were measured online and real-time, and the changes of the microstructures of the samples after drying were further detected, and the dynamic changes of temperature and quality during microwave drying were analyzed.

The results show that when the relative moisture content is 30%, only the discontinuous section of the material will be scorched, while when the relative moisture content is 15%, the surface of the material will be scorched, and the scorch will be aggravated at the discontinuous section. The temperature change of the material in the microwave drying equipment can be divided into three stages: the fast heating stage, the constant temperature stage and the slow heating stage, and the temperature in the microwave chamber will increase with the power as a whole. Increase.

When the power is fixed, the material dehydration mainly occurs in the constant-speed rising stage of weight loss rate. At 0.60 kW, the material with different thickness (0.40 cm, 0.80 cm and 1.20 cm) loses water 42.39%, 48.29% and 49.40%, respectively, at 0.80 kW, 49.23%, 52.95% and 53.01% at that stage, and at 1.00 kW, 46.95%, 64.72% and 62.59% at that stage, respectively.

Key words: microwave drying of apples; relative moisture content; drying power; material thickness

Fruit and vegetable crisps are a kind of popular snack food. They are not only crisp and delicious, but also retain the original color, fragrance and taste of fruits and vegetables to a large extent. They are rich in dietary fiber and have broad production potential and consumption potential.

At present, the main drying methods for producing fruit and vegetable crisp chips are hot air drying, far infrared drying and vacuum freeze drying. Although the quality of far infrared drying and vacuum freeze drying products is good, the investment cost is high, while the traditional hot air drying has the problems of long drying time, high energy consumption and unstable quality of dried products, which greatly limit the production of fruit and vegetable crisp chips. The scale, intensive and energy-saving efficiency of the project are improved.

Due to the advantages of fast drying speed, high thermal efficiency and uniform heating, microwave drying technology has attracted more and more attention in the fields of agricultural production and food processing, especially in the drying of grain (such as rice, wheat, corn, etc.), vegetables (such as peas, onions, peppers, etc.) and fruits (yellow peach, litchi, etc.). Successfully applied to actual production.

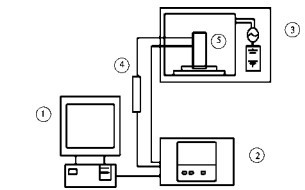

In order to explore the relationship between drying power, temperature and moisture content of apple slices in microwave drying process and optimize microwave drying process, the micro-structure changes of apple slices dried to different relative moisture content were analyzed and compared by microwave drying system with on-line weighing and temperature measurement. The heat and mass transfer rules were summarized, and the technological basis of microwave drying process of apple slices was obtained. Parameters.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply