- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave assisted foam drying of papaya pulp

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave assisted foam drying of papaya pulp

2018-12-26 16:27:56

Abstract: papaya powder was prepared from Papaya by microwave assisted foam drying. The effects of monoglyceride and soy protein isolate on the foaming characteristics of fruit pulp were investigated. The microwave drying equipment was studied, and the parameters of microwave foam drying technology were optimized, and the best formulation of foaming agent and drying technology of papaya were determined.

The results showed that adding 6.83% monoglycerides and 6.56% soy protein isolate to papaya pulp had the highest foam expansion rate and good foam stability. The optimum conditions for microwave foam drying of papaya pulp were microwave power 578 W, material thickness 4.90 mm and drying time 6.65 min.

Key words: papaya microwave drying, foam drying, papaya pulp, foaming characteristics, vitamin C content

Papaya, also known as papaya, milkmelon, longevity fruit, is a large perennial tropical and subtropical evergreen cork herb, small evergreen cork trees, widely planted in Lingnan region of China, known as "fruit emperor" and "Baiyi fruit". Containing a variety of amino acids, minerals such as calcium, iron and carotene, it is very popular because of its rich nutrition. The content of vitamin C in fresh fruit is very high, reaching 48 mg. 100 g-1. It can be eaten fresh, and can also be made into drinks, preserved fruits, fruit powder and other products.

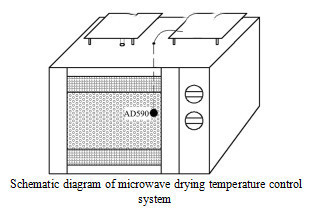

After harvesting mature papaya, it has strong respiratory function, easy to deteriorate and corrupt, short shelf life, and is not easy to store and preserve. In order to prolong the shelf life, it can be dried. The dried products have unique taste and good flavor, long shelf life, easy to eat and transport. Microwave drying is a kind of medium heating drying based on the principle of dielectric loss. The main heating mechanisms are ion conduction and dipole rotation. In this process, the frictional action produced by the molecule inside the material makes the molecule gain energy and produce remarkable thermal effect.

Microwave heating both inside and outside the material, therefore, the temperature gradient of the material is consistent with the direction of water vapor discharge, which improves the condition of moisture migration in the drying process, makes moisture diffuse to the surface of the material continuously, accelerates drying speed and improves drying efficiency. However, microwave drying alone may result in the destruction of heat-sensitive components, loss of nutrient components, poor color and flavor of products, and other undesirable phenomena.

Foam drying is suitable for drying food materials with high viscosity, high heat sensitive substances and high sugar content. The microwave assisted foam drying process first froth the material and form a porous structure, which makes the water evaporate quickly by increasing the surface area of the material. When foaming is added, proper stabilizer is added to ensure a stable and uniform foam structure, and the foam density is suitable for the range of 0.2 ~ 0.6 g / cm ~ 3 of microwave drying.

At present, this technology is a new technology, and there is no large-scale production. Although domestic and foreign scholars have done some research on this technology, there is no experimental research on papaya pulp microwave assisted foam drying technology. Through the combination of microwave drying and foam drying, the processed fruit powder can basically maintain the original color, flavor and nutritional components of fresh fruits, optimize the technological conditions of products, and improve the quality of products.

The dried products can be ground into powder and used as concentrated fruit juice beverage with stable properties and convenient use. It can also be directly added to food as an adjuvant. The microwave assisted foam drying technology of papaya pulp was studied in order to optimize the microwave assisted foam drying technology of papaya pulp, which has certain theoretical and practical significance in guiding the actual industrial production.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply