- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Application of Microwave Drying in Taro Chips Processing

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Application of Microwave Drying in Taro Chips Processing

2018-12-28 14:13:33Absrtact: Taro was used as raw material, microwave drying equipment and vacuum oil bath were used to study the effects of different processing parameters on water content, oil content and sensory quality of products, and a new processing technology of taro chips was established.

The results showed that taro chips with low oil content, smooth appearance and good crispness could be obtained by vacuum oil bath (initial oil temperature 110 C, termination oil temperature 98 C and vacuum degree 0.098 MPa) for 5 minutes, controlling moisture content of products between 30% and 35%, and then microwave drying (microwave power 1 200 W) for 60 minutes. The oil content of the products processed by this new process is low, and the energy saving is 23% compared with the traditional process. It is a feasible new processing technology for fruit and vegetable crisps.

Key words: microwave drying taro; vacuum oil bath;

Fruit and vegetable crisps are instant fried fruits and vegetables from various fresh fruits and vegetables under vacuum and low temperature. They are popular in domestic and foreign markets because of their advantages of pure nature, high nutrition, low calorie and low fat. At present, the most common processing technology is "low temperature vacuum oil bath (dehydration)" method, which produces crisp fruit and vegetable chips with crisp taste and natural color.

But its main disadvantage is that when fruit and vegetable products are dehydrated in oil, it usually takes 20 minutes to 60 minutes, which directly results in high oil content of the products, which does not conform to the modern dietary concept; on the other hand, excessive use of oil and long processing time will also produce some harmful substances in the products, at the same time, long processing time and high energy consumption.

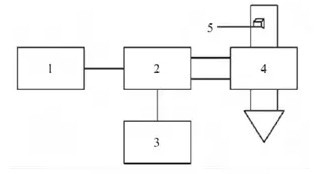

Taro was selected as raw material, aiming at the shortcomings of high oil content and high energy consumption of existing products, microwave dehydration technology was combined with traditional low-temperature vacuum oil bath, and the characteristics of microwave dehydration were fully applied to process combination and optimization, in order to establish a fast, efficient and energy-saving new processing technology for fruit and vegetable crisps, and to provide guidance for production and application.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply