- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Comparative Study on Different Drying Technologies of Citrus Bergamot in Sichuan Province Based on Multi-index Component Analysis

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Comparative Study on Different Drying Technologies of Citrus Bergamot in Sichuan Province Based on Multi-index Component Analysis

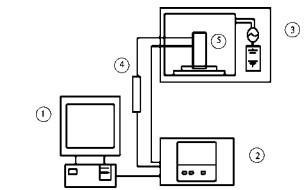

2019-01-11 13:48:08ABSTRACT: Objective: To study the effects of different drying methods on the quality of Sichuan bergamot. METHODS: With the contents of hesperidin, polysaccharide and volatile oil as indexes, the effects of different drying methods on the quality of Citrus Bergamot were compared by optimizing oven drying, microwave drying equipment and hot air drying technology.

Result: The optimum drying technology of oven drying is 50 C, 8 h, laying one layer; the optimum drying technology of microwave drying is 75 C, 1 h, 500 W, laying two layers; the optimum drying technology of hot air drying is 75 C, 1 h, 1.0-1.2 m s-1, laying. The contents of hesperidin, polysaccharide and volatile oil in Sichuan Bergamot treated by microwave drying and hot air drying were significantly higher than those treated by oven drying. CONCLUSION: Microwave drying and hot air drying are suitable for the drying of Sichuan Bergamot medicinal materials.

Key words: Sichuan Bergamot microwave drying; hot air drying; oven drying; hesperidin

Bergamot is the dried fruit of Rutaceae plant bergamot, which is mainly produced in Sichuan, Yunnan, Zhejiang, Guangdong, Guangxi, Fujian and other places. It can be divided into Sichuan bergamot, golden bergamot, Guangzhou bergamot and Jian Bergamot according to its origin. It is mainly produced in Gaoyao, Zhaoqing, Lingle, Guanyang, Daxin and other places in Guangdong, called "Guangfoshou". It is mainly produced in Fuan, Putian and other places in Fujian, called "Jianfoshou". It is mainly produced in Hejiang, Jiangjin, Shanghai and other places in Sichuan, Yimen, Binchuan and other places in Yunnan, called "Sichuan Foshou". It is mainly produced in Jinhua, Zhejiang, called "Zhejiang Foshou" or "Jinfoshou".

Sichuan Bergamot has the functions of soothing liver, regulating qi, drying dampness and resolving phlegm, anti-depression, anti-cancer, improving immunity and so on. It has good prospects for development. Studies have shown that the chemical constituents of Sichuan Bergamot mainly include hesperidin, polysaccharide and volatile oil. These constituents have certain biological activity in treating cough and asthma, depression, cancer, low immunity and other diseases. The content of these constituents directly affects the quality of Sichuan bergamot. At present, there is no report on the drying method of Sichuan bergamot. This experiment combines traditional and modern technology to dry Sichuan bergamot. By comparing the content changes of its main components, the suitable drying method of Sichuan Bergamot is discussed to minimize the loss of its effective components in the drying process.

After consulting the literature and analyzing the single factor test results, the volatile oil was extracted by steam distillation. The extraction process was 10 times the amount of water added and extracted for 6 hours. Because the content of volatile oil in Sichuan Bergamot was relatively low, about 0.1%~2.0%. In order to ensure the extraction quantity of volatile oil, the sample size of this experiment was 200 g, so as to achieve accurate reading.

According to the literature, drying methods of Chinese medicinal materials include sun drying, shade drying, drying, freeze drying, microwave drying, hot air drying, etc. Among them, traditional drying methods such as sun drying, shade drying and drying are not stable. It is of great significance to adopt modern drying technologies such as freeze drying, microwave drying and hot air drying.

The drying methods of bergamot include stir-frying, drying, microwave drying and other processing methods. The content of total polysaccharides and flavonoids was determined by ultraviolet-visible spectrophotometry. In this experiment, the contents of hesperidin, polysaccharide and volatile oil were taken as indicators, and the optimized oven drying process, microwave drying and hot air drying process were compared comprehensively. The results were more scientific and reasonable than the single index evaluation.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply