- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave Drying Process Simulation and Application of Lycium Barbarum L. Based on Weibull Distribution Function

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave Drying Process Simulation and Application of Lycium Barbarum L. Based on Weibull Distribution Function

2019-01-16 13:54:39

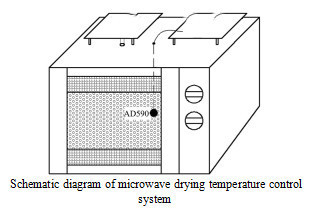

ABSTRACT: In order to explore the influencing factors of Weibull distribution function and its application in microwave-hot-air drying of wolfberry, the drying conditions of wolfberry under different pulse ratio (pulse ratio 1.5:2 min/1 min; pulse ratio 1.67:3 min/2 min; pulse ratio 2:1 min/1 min), microwave power (185, 200, 215 W) and moisture content (30%, 40%, 50%) were studied. The drying process was studied. The Weibull distribution function was used to simulate the drying kinetics curve, and the effective diffusion coefficient of water and drying activation energy of Lycium barbarum microwave drying equipment were analyzed by the Weibull model.

The results show that Weibull distribution function can well simulate the microwave drying process of Lycium barbarum L. The scale parameter a is related to microwave pulse ratio, microwave power and moisture content, and decreases with the increase of microwave power, and increases with the increase of microwave pulse ratio and moisture content, while the initial moisture content, pulse ratio and microwave power have little influence on shape parameter beta. The effective water diffusion coefficient of Lycium barbarum L. was 1.7 *10-5~3.2 *10-5 m2/h and the drying activation energy of Lycium barbarum L. was 54.78 kJ/mol.

Key words: Weibull distribution function; microwave drying of wolfberry; effective diffusion coefficient; drying activation energy

Lycium barbarum L. is a special product of Ningxia. Except for a small amount of fresh food and processing raw materials, most of it is used for drying. Under normal temperature, Lycium barbarum is easy to decay and deteriorate due to the action of microorganisms and enzymes, which makes it difficult to store for a long time and shortens its shelf life greatly. If fresh Lycium barbarum is processed into dry products, the shelf life of the products can be prolonged, and the cost of preservation and transportation can also be reduced.

Natural air drying has a long drying cycle, is susceptible to pollution and is severely affected by environmental factors. The loss of effective ingredients is large, the drying quality is extremely unstable, and the phenomena of decay, blackening, browning and sugar spillover are easy to occur. Although hot air drying can meet the needs of industrial production, the drying time is longer, generally 72 hours. Lycium barbarbarum is nutrient-dispersed, energy utilization is low and pollutes the environment. Microwave drying can greatly improve the drying rate of Lycium barbarum L.

In recent years, microwave intermittent drying technology has been widely used in the production and processing of agricultural products. Microwave drying has the advantages of short heating time, high thermal efficiency and good drying quality. However, at present, microwave drying mostly adopts constant power continuous drying method. It is easy to cause material burns, marginal coking, crusts and hardening during the drying process. Liu Zhijun used the microwave intermittent drying method to study the Masson pine, and found that the microwave drying rate was faster, but its technological parameters were not applicable to Lycium barbarum.

Chen Jiankai dried Pleurotus eryngii by microwave vacuum drying and got Page model, which could not reflect the microwave drying process of Lycium barbarum; Wang Shunmin dried spinach by hot air and microwave, only obtained the technological parameters and did not analyze the drying process. Compared with traditional drying methods, microwave intermittent drying not only has shorter heating time and lower drying cost, but also can effectively avoid burning agricultural products due to overheating and ensure drying quality. So far, the research on drying of Lycium barbarum has not been seen, so it is necessary to study it in depth.

In this paper, the effects of microwave power, moisture content of wolfberry and microwave pulse ratio on drying kinetics of wolfberry were studied. The drying process was simulated by Weibull function, and the influencing factors of parameters in Weibull distribution function were explored. The basis for predicting and regulating the processing process of wolfberry microwave drying was provided, and the Weibull distribution function was also used in wolfberry microwave drying. The application of processing provides theoretical support.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply