- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying methods on the quality of walnut green peel

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying methods on the quality of walnut green peel

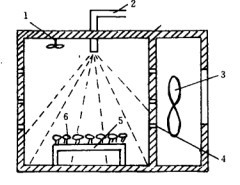

2019-01-17 09:26:12Absrtact: Walnut green peel was dried by sun drying, shade drying, hot air drying, microwave drying and mid-short wave infrared drying. The effects of different drying methods on moisture content, color difference, total phenols, total flavonoids and anthraquinones content and drying time of walnut green peel were studied.

The results showed that the drying time of microwave drying equipment was the shortest, 0.4 h, and the drying rate was significantly higher than that of other drying methods (p < 0.05), followed by medium and short wave infrared drying, which lasted 8 h. The contents of total phenols, flavones and anthraquinones in the dried green peel were 46.98, 13.79 and 5.37 mg/g, respectively, which were significantly higher than those in other drying methods (p < 0.05).

The contents of total phenols, flavonoids and anthraquinones in walnut green peel dried by mid-short wave infrared were 43.13, 12.23 and 4.36 mg/g, respectively. The color of walnut green peel powder dried by hot air at 50 (?) C was the lightest, and the value of E* was 65.05; the value of E* was 67.98, followed by that of mid-short wave infrared drying. Comparing the five drying methods, the product quality obtained by sun drying is the best, but it is greatly influenced by the weather. In rainy weather, there is no obvious difference between the quality of walnut green peel dried by 50 C hot air and mid-short wave infrared, but the drying time of mid-short wave infrared is only 1/3 of that of 50 C hot air, which is more efficient and more suitable for the drying of walnut green peel.

Key words: walnut microwave drying, total phenols, total flavonoids, anthraquinones

China is rich in walnut resources and has become a major walnut producer in the world. The area of walnut cultivation has reached more than 80 million mu, and the total output of walnut has reached 3 million tons. The output of walnut green peel is also 3 million tons. The processing and utilization of walnut fruits are mainly concentrated in the production of walnut oil, walnut protein, walnut milk and other walnut products. As a byproduct of walnut production, the utilization rate of walnut green peel is very low.

After harvesting, a large number of green peels are piled randomly, which wastes resources and pollutes the environment seriously. The allelochemicals contained in the green peels of walnuts flow to the farmland to inhibit the growth of other plants, but also pollute the water source. It is necessary to collect the green peels of walnuts, dry them for further processing, reduce pollution and turn waste into treasures.

Walnut green peel contains phenols, flavonoids, quinones and other organic substances, which can be used to prepare cosmetics and drugs. Salejda et al. found that walnut quinone and some phenolic compounds in walnut green peel could improve the sensory quality of sausage and prolong its storage period. Wang Gangxia et al. found that polyphenols and anthraquinones in walnut green peel had significant inhibitory effects on several major Postharvest Pathogenic fungi, and the inhibitory effects were positively correlated with their concentrations.

Zhao Xingyu et al. found that polyphenols in green peel of Juglans mandshurica had protective effects on endogenous H2 O 2-damaged vascular endothelial cells. Ding Yun et al. studied the dyeing properties of cotton fabric with subcritical water extract of walnut green peel. It was found that the dyeing effect of cotton fabric was better when mixed with metal salts such as Fe3+, Cu2+, Sn2+, and so on, and the dyeing chromatographic range could be expanded.

After harvesting, walnut green peel should be dried and preserved to facilitate later processing and utilization, but the drying of walnut green peel has not been reported in the literature. The aim of this study was to investigate the effects of different drying methods, such as sun drying, shade drying, hot air drying, microwave drying and mid-short wave infrared drying, on the content of polyphenols, flavonoids, anthraquinones and powder color of walnut green peel, in order to provide basis for the drying, preservation and deep processing of walnut green peel.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply