- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Summary of Several Drying Methods of Lycium barbarum L.

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Summary of Several Drying Methods of Lycium barbarum L.

2019-01-18 15:41:57

Absrtact: In order to improve the quality of dried products and achieve the purpose of saving cost and increasing efficiency, the working principles of different drying methods were introduced, and the advantages and disadvantages of different microwave drying equipments and their effects on the quality of wolfberry were analyzed. According to the current research status of drying methods of Lycium barbarum, the future development trend was prospected, in order to provide theoretical reference for the research of drying methods of Lycium barbarum and its application in industry.

Key words: Lycium barbarum microwave drying; drying methods; research progress

Lycium barbarum, also known as Lycium barbarum, is a kind of Lycium barbarum plant of Solanaceae with a history of planting and using for more than 2000 years. Because of its rich nutrition and the advantages of medicinal and food homology, it has always been considered as a good health product. In order to meet the needs of consumers, wolfberry is planted and sold by farmers as cash crops, bringing about certain economic income. With the development of economy and the improvement of people's living standards, great health has become a generally accepted concept of life and fashion pursuit. Wolfberry is just a tonic to comply with the theory of great health, which shows its broad prospects for development.

Although wolfberry resources are all over the world, only China has the most extensive comprehensive development of wolfberry, and Chinese wolfberry has become the most important consumption place of wolfberry in the world, especially in Ningxia, known as the home of wolfberry, wolfberry industry is a characteristic local industry supported by the government, highly concerned and supported by local governments, and has certain policy advantages. However, the development of Chinese wolfberry industry is slow, and it did not enter the stage of rapid development until 2008.

At present, there are more and more kinds of products produced and sold from Lycium barbarum as raw materials on the market. They are not only sold in the form of dried fruits, but also intermediary products and final products such as fresh fruits, alcoholic drinks, snack foods, Lycium barbarum polysaccharide powder and health food with Lycium barbarbarum polysaccharide as functional components.

With the development trend of food health, wolfberry industry keeps pace with the times and coincides with China's policies. With the policy as a powerful driving force, wolfberry industry has developed rapidly in recent years, which has promoted the economic income of wolfberry farmers and the development of wolfberry industry. The fresh fruits of Lycium barbarum are berries, which have high moisture and sugar content and are prone to mildew. The results showed that the fresh fruits of Lycium barbarum could grow mould on the first day without any treatment. The rate of mould on the second day could reach 30%-40%, and the rate of mould on the third day could reach 50%-80%.

In order to reduce the huge economic loss caused by the loss of fresh fruits of Lycium barbarum after harvest, people choose to mainly dry the fruits of Lycium barbarum. Therefore, there are two main types of Lycium barbarum products on the market at present. The first is the dried fruit products with Lycium barbarum as raw material, the second is the dried fruit products with Lycium barbarum as raw material or the health food developed with a functional component of Lycium barbarum.

Because of the storage, transportation and the shelf life of Lycium barbarum products and their products caused by the problem of preservation of Lycium barbarum, the research on drying methods of Lycium barbarum has become an urgent problem to be solved in Lycium barbarum industry. Therefore, drying technology of Lycium barbarum is becoming more and more important in the future development of Lycium barbarum industry.

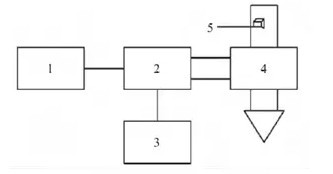

Studies have shown that drying is a food processing technology that inhibits microorganisms and deterioration by controlling water content, and has many advantages such as convenience and cost reduction. At present, natural air drying is the simplest drying method, which is commonly used in small farmers. Hot air drying and vacuum freeze drying are also used in industry. In addition, with the development of science and technology towards multi-technology integration and high-tech, some new drying technologies have emerged and developed. Especially, different drying combinations have been gradually formed and applied in the drying of food industry.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply