- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimization of microwave drying technology for Maize

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimization of microwave drying technology for Maize

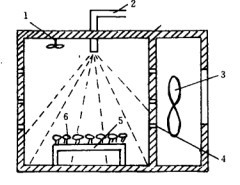

2019-01-19 09:26:22Absrtact: Microwave drying method was used to dry corn reconstituted rice. Six factors, including material thickness, microwave drying equipment, microwave power, hot air speed, hot air temperature and hot air time, were selected to optimize the drying process by quadratic general rotary combination design method.

The results show that the optimum technological conditions are material thickness 6 m m, microwave time 6 min, microwave power 1800 W, hot air speed 1 m/s, hot air temperature 40 C and hot air time 15 min. Under these conditions, the drying rate was 0.57 kg/kg.min, the bursting waist rate was 5% and the sensory evaluation was 87. Microwave-hot air combined drying is suitable for the drying of corn reconstituted rice, which is a fast drying method with better product quality.

Key words: corn microwave drying; hot air; combined drying; quadratic general rotary combination design

Corn is the main food crop in China, and its nutritional value is high. At present, corn products have gradually entered into daily life. Corn recombinant rice is a product made from corn by extrusion and shearing. At present, the development of recombinant rice at home and abroad has made phased progress.

Scelia and others used corn flour as the main raw material to obtain recombinant rice with good rehydration. Yoon et al. obtained the reconstituted rice with outstanding functional properties, good physical and chemical properties and good taste. Soo et al. obtained nutritious recombinant rice. Wujie et al., Fan Juan et al. and Chen Lin all use maize as their main raw materials to extrude and obtain nutritious and easy-to-cook reconstituted rice.

Drying is one of the key technologies in the production of corn recombinant rice, which has a great impact on the quality of rice. Therefore, the research on drying technology of corn recombinant rice is of great significance and can provide theoretical basis for the industrialization of corn recombinant rice production.

Microwave drying utilizes the principle of dielectric loss. Because of the large loss factor of moisture in the material, it can absorb a large amount of microwave energy and convert it into heat energy to promote internal water evaporation. Microwave drying has fast speed and high thermal efficiency, but this drying method has high energy consumption and high drying cost.

Hot air drying is to heat the air in a hot air stove, and the hot air is fed into the oven by a fan to contact the sample for heating and drying. This method has the advantages of low cost, large processing capacity, easy operation and automation, but the loss of effective components is large and the quality is poor.

Microwave-hot air combined drying method can make up for the shortcomings of microwave and hot air in drying, reduce energy consumption and save drying time, while ensuring better quality of products. Microwave-hot air combined drying has been widely used in the drying of fruits, vegetables and grain. Studies such as Jiao Aiquan show that the drying time of microwave combined hot air drying is shorter than that of hot air drying and microwave drying. Xu Yanyang et al. analyzed the change rule of maize moisture with drying time in drying process and established corresponding mathematical model.

Guixing Ren et al. showed that the combined drying method could shorten the drying time and maintain the quality of American ginseng. Ana Andrees et al. have shown that microwave power has a greater effect on the sample than temperature. A. A. Gowen et al. showed that microwave power and hot air temperature affected the dehydration rate, rehydration rate and color difference of premature soybean.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply