- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of different drying methods on quality of dried Tremella fuciformis products

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of different drying methods on quality of dried Tremella fuciformis products

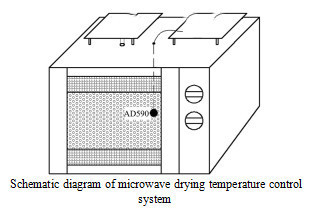

2019-01-19 09:38:43Abstract: The sensory quality, rehydration ratio, shrinkage and color of dried Tremella fuciformis products were taken as evaluation indexes to study the effects of four different drying methods on the quality of dried Tremella fuciformis products: hot air drying, vacuum drying, microwave drying and freeze drying.

The results showed that the dried Tremella fuciformis products dried by hot air at 60 C had the best sensory quality, and the rehydration ratio, shrinkage rate and comprehensive score were second only to freeze-drying; the vacuum drying effect was lower than that of hot air drying; the quality of microwave drying equipment was the best; the comprehensive quality of freeze-drying products was the best, but the drying time was longer, and the product structure was loose and brittle. The comprehensive quality of dried ear products is the best, and the drying method is simple and the cost is low.

Key words: Tremella fuciformis microwave drying; quality

Tremella fuciformis, also known as white fungus and snow fungus, is the fruiting body of Tremella fuciformis fungus. It is an important edible fungus. It contains polysaccharides, phenols, flavonoids and a variety of amino acids. It is known as the "king of edible fungi" and is a kind of high-quality effective component extraction resources. Fresh Tremella fuciformosa has a high moisture content, generally 75%-80%. It is very difficult to preserve, even under suitable conditions. It can only be stored for about two weeks.

Dehydration drying is one of the important methods widely used in food processing. Drying methods of Tremella fuciformis mainly hot air drying, microwave drying, vacuum drying, freeze drying and so on. At present, the effects of different drying methods on the quality of carrot, chestnut, lotus seed, apple slices, garlic and other agricultural products have been reported, but the research on drying processing of tremella fuciformis still less.

In this experiment, fresh Tremella fuciformis was used as raw material to study the effects of four different drying methods, hot air drying, vacuum drying, microwave drying and freeze drying, on the sensory quality, rehydration ratio, shrinkage rate and color of Tremella fuciformis dried products, in order to obtain the processing characteristics of different drying processes of Tremella fuciformis and provide scientific basis for improving the quality of Tremella fuciformis dried products.

Hot air drying (60 C) Tremella dry products have the best sensory quality, its comprehensive score, rehydration ratio and shrinkage rate are only second to freeze drying, but with the increase of hot air drying temperature, its sensory quality and rehydration ratio decrease, yellowness and shrinkage rate increase; vacuum drying effect is lower than hot air drying, and its drying effect with the increase of vacuum drying temperature and hot air drying performance. The same trend

Microwave drying has the best effect; freeze drying has the worst effect, but the drying time is longer, and the product structure is loose and brittle, which is not conducive to the packaging and transportation of products. Considering comprehensively, hot air drying (60 C) products have better comprehensive quality and simple drying method, which is a better drying method.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply