- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Drying Characteristics of Ginger Based on Odor Detection

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Drying Characteristics of Ginger Based on Odor Detection

2019-01-24 13:13:26ABSTRACT: Volatile odors of dried and dried samples were collected at four constant drying temperatures of 50, 60, 70 and 80 (?) respectively. The change of odor profiles and the relationship between flavor emission intensity and drying characteristics at different temperatures were analyzed, and the quality of dried ginger was compared.

The results show that the microwave drying equipment avoids scorch, but the odor emits more because of the long drying time.

On the contrary, the drying time is shorter in high temperature drying, but the quality of the product is poor because of the smell of coke paste. Water evaporation will accompany the loss of volatile flavor. In order to achieve the best performance of odor retention and inhibiting coke paste, and to ensure the quality after drying, the original flavor retention and inhibiting coke paste performance at 60 C is better, and the color retention effect and rehydration are the best.

Key words: ginger microwave drying; odor detection; drying process; quality

Ginger is the tuber of ginger, also known as fresh ginger and old ginger. Ginger has complex chemical constituents, including carbohydrates, proteins, vitamins, minerals, spices, oils and a small amount of volatile oils.

Ginger contains gingerol, aromatic alcohols, gingerene, aromatic alkene, cintene, amino acids, nicotinic acid, citric acid, linalool and other functional substances. It has the effects of curing toothache, treating arthritis, lowering cholesterol, preventing cholelithiasis, anti-motion sickness, anti-atherosclerosis, anti-aging and anti-cancer.

Ginger is widely used in cooking spices, seasonings and herbs because of its special flavor. The sensory characteristics of ginger flavor are mainly attributed to ginger essential oil, which is the volatile oil in ginger and provides aroma and flavor for ginger. Ginger is not easy to keep fresh, fresh raw materials are difficult to meet the market and people's consumption needs. Ginger sprouts and roots when the storage temperature is higher than 15 C, but freezing damage occurs when the temperature is lower than 10 C, which seriously affects its storage quality, reduces its edible value and appearance quality.

Different drying processes have different effects on the aromatic flavor and pungent taste of ginger. The aroma of ginger mainly comes from volatile flavor substances. Ding et al. and Huang et al. used headspace solid-phase microextraction (HSSPME) combined with gas chromatography-mass spectrometry (GC-MS) to compare the effects of different drying processes on volatile flavor compounds of ginger. It was found that microwave drying of ginger had more advantages in retaining volatile components.

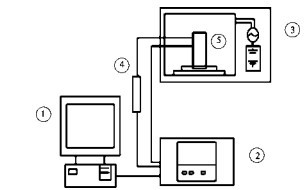

However, up to now, little research has been done on the odor changes during ginger drying. Through the on-line odor detection system of microwave drying, the central temperature of ginger was controlled in the process of microwave drying. The effects of temperature on odor diffusion, drying characteristics and quality of ginger after drying were studied. The better microwave drying conditions were determined, which could provide reference for the production and application of microwave drying ginger.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply