- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of different drying methods on the quality of pumpkin powder

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of different drying methods on the quality of pumpkin powder

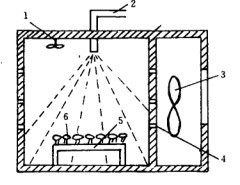

2019-01-25 09:47:48Absrtact: Pumpkin powder was dried by hot air drying, microwave drying equipment and vacuum drying. The effects of drying methods on the quality of pumpkin powder were studied. The results showed that hot air drying had the highest total phenol content and the lowest content of beta-carotene, solubility and rehydration.

Microwave drying had the highest b* value, bulk density, solubility, rehydration, water holding capacity and oil holding capacity, and the lowest L* value, a* value and VC content; vacuum drying had the highest L* value, a* value, VC content and beta-carotene content, and the lowest total phenol content, bulk density, solubility, water holding capacity and oil holding capacity. In order to ensure the nutritional quality of pumpkin powder, and considering the appearance quality of pumpkin powder, vacuum drying is the best way to prepare pumpkin powder.

Key words: pumpkin microwave drying; drying method; quality

Pumpkins belong to Cucurbitaceae. In addition to carotene, pumpkin polysaccharide, vitamins, free amino acids and mineral nutrients, it also contains a large number of cucurbitacin, alkaloids, pumpkin seed alkaloids and pectin and other active ingredients. It has many health functions, such as reducing blood sugar, lipid, anti-aging and so on.

Fresh pumpkin has high water content and can not endure storage. Therefore, processing fresh pumpkin into dehydrated powder can not only make full use of pumpkin resources, but also improve its processing additions. At the same time, the nutrients in pumpkin are also kept to the maximum extent, which effectively broadens the way of processing and eating pumpkin.

Choosing a scientific drying method is the key to the preparation of pumpkin powder. Therefore, different drying methods were used to prepare pumpkin powder, and the effects of drying methods on the quality of pumpkin powder were studied in order to provide theoretical basis for the processing and utilization of pumpkin and expand the processing technology and product types of pumpkin.

Microwave drying has the highest solubility, followed by hot air drying, and vacuum drying has the lowest solubility. The results showed that the cell wall breakage rate of pumpkin slices dried by microwave was high, the specific surface area was greatly increased, the release of active ingredients was promoted, the physical and chemical adsorption properties were increased, and the solubility of pumpkin powder was improved.

The water holding capacity and oil holding capacity of microwave drying are higher than those of hot air drying and vacuum drying. This may be due to the different drying process and the different particle structure of the prepared pumpkin powder. The amount of hydrophilic and lipophilic groups exposed by microwave drying of pumpkin powder increases the chance of the combination of water molecules and hydroxyl groups, thus improving the ability of water and oil retention.

The drying method of pumpkin has great influence on its preparation quality. Among the three drying methods, hot air drying had the highest total phenol content, the lowest L* value, a* value, b* value, VC content, bulk density, water holding capacity and oil holding capacity, and the lowest content of beta-carotene, solubility and rehydration.

Microwave drying had the highest b* value, bulk density, solubility, rehydration, water holding capacity and oil holding capacity, the middle content of beta-carotene and total phenol, the lowest content of L* value, a* value and VC, the highest content of L* value, a* value, VC content and beta-carotene in vacuum drying, and the middle content of rehydration, the lowest content of total phenol, bulk density, solubility, water holding capacity and oil holding capacity. In conclusion, vacuum drying is the best way to prepare pumpkin powder under experimental conditions.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply