- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on the production of red jujube powder dry aid by microwave drying jujube pulp

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on the production of red jujube powder dry aid by microwave drying jujube pulp

2018-11-12 09:16:05

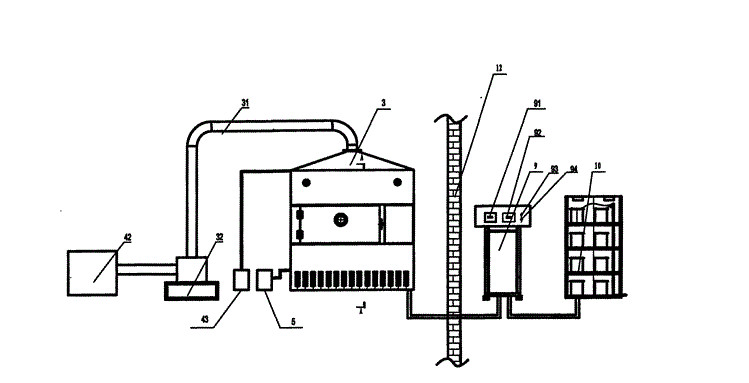

Abstract: In order to determine the optimum ratio of dry-dried red jujube powder to microwave-dried jujube powder, based on the determination of microwave drying conditions in the previous experiments, the single factor and orthogonal experiments were applied to microwave drying jujube powder. The powder collection rate and sensory evaluation indicators were comprehensively evaluated to investigate the effect of microwave drying.

The results showed that the microwave drying equipment was the main dry aid for maltodextrin, the ratio of the total solids of jujube pulp to the main dry agent was 4:6, the microwave power was 360 W, and the intermittent microwave heating method was 10 s/60 s. When the thickness of the material is 4 mm, the optimized optimum ratio of the dry aid is 15.0% of β-cyclodextrin, 2.5% of soy protein isolate, 13.0% of soluble starch, and 3.0% of lecithin. The optimized technical process can achieve the maximum saving of production energy consumption, improve the powder collection rate and sensory evaluation effect of the product, and the appearance color of the product is red to slightly yellow.

Key words: microwave drying jujube powder; dry aid;

At present, the methods for producing fruit and vegetable solid powder beverages mainly include vacuum freeze drying, fluidized bed drying and spray drying. Although the vacuum freeze-dried dry product is good in quality, the investment cost is high, and the fluidized bed drying has problems such as drying efficiency, low energy utilization rate, and poor dry product quality. Spray drying is better, but due to the high sugar content of red dates, spray drying is more difficult. The microwave drying has a short heating time, uniform heating, high thermal efficiency, sterilization, and good dry product quality.

Microwave drying mainly utilizes the heating and penetrating properties of microwaves. Due to the large loss of moisture medium in the material, the microwave energy can be absorbed in a large amount and converted into heat energy. Therefore, the temperature rise and evaporation of the material are simultaneously performed in the entire object, so that the microwave drying has the characteristics of drying from the inside to the outside, and overcomes the conventional In the drying, the outer layer of the material is first dried to form a hard shell knot, which hinders the internal moisture from continuing to move outward.

Based on the characteristics of high sugar content of jujube, this study determined the process parameters of microwave drying on the basis of pre-experimental experiments, focusing on maltodextrin as the main dry aid, other kinds of dry aids and additions (mainly assisted The effect of the percentage of dry agent on the effect of microwave drying jujube powder provides technical support for the deep processing development and utilization of jujube, and provides a theoretical basis for the promotion of factory-made microwave drying jujube powder technology.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply