- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying methods on the quality of lotus root chips

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying methods on the quality of lotus root chips

2018-10-30 15:32:23

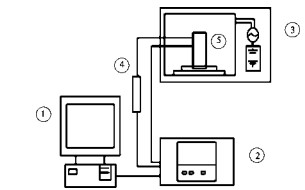

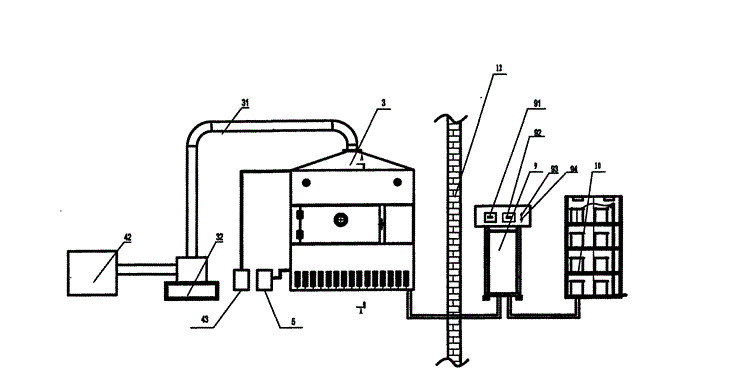

ABSTRACT: In order to determine the best drying method for leisure lotus root crisp slices, six different drying methods were adopted, including hot air drying, microwave drying equipment, hot air-vacuum microwave drying, hot air-air puffing drying, vacuum Microwave-Air puffing drying, hot air-vacuum Microwave-Air puffing drying. After drying, the quality indexes such as color, shrinkage, hardness, brittleness, VC retention, polyphenol retention and microstructure were analyzed.

The results showed that hot air drying had little effect on the color of lotus root crisp slices, but the hardness was too low, brittleness was poor, VC and polyphenol loss was the most serious; vacuum microwave drying lotus root crisp slices VC and polyphenol retention rate was high, brittleness was good, but the hardness was too high, product shrinkage was serious, color difference and browning were high; The quality of lotus root crisp slices was better than that of single drying. The shrinkage and browning degree of lotus root slices dried by hot air-vacuum Microwave-Air puffing were significantly lower than that dried by vacuum microwave drying, while the retention rate of VC and polyphenols was significantly higher than that dried by hot air drying. The hardness, brittleness were moderate and the porosity was good. To sum up, hot air-vacuum Microwave-Air puffing drying is the most suitable method for processing lotus root leisure crisp slices.

Key words: lotus root microwave drying; drying method; crisp chips;

Nelumbo nucifera Gaertn L., a large perennial perennial perennial perennial aquatic herb of the genus Nelumbo, has a white flesh, crisp and sweet taste, and is rich in carbohydrates, proteins, vitamins, minerals, tannins and polyphenols and other nutritional and functional components, so it is widely accepted by consumers. Love. A large number of boiled lotus root, salted lotus root and dehydrated lotus root slices are exported to Japan, Korea, Singapore, the Philippines, the United States and other countries every year in China. However, the nutrient composition and flavor of lotus root are seriously damaged by boiling and salting treatment methods, and the added value of the product is low because of its simple processing method and low technical content. Therefore, it is of great significance to carry out the research of lotus root deep processing, reduce the loss of nutrition and flavor deterioration in the process of material processing, and improve the added value of products.

As an important processing unit, drying is widely used in modern food industry. Drying can reduce the moisture content of materials to a certain extent, effectively hinder the growth of spoilage microorganisms in materials and the occurrence of chemical reactions with water as the medium, thus significantly prolonging the shelf life of food and reducing the cost of storage and transportation, but the physical and chemical changes of materials during drying process will directly affect the quality of final products. Therefore, the research on the quality of dried products has become a hot topic in recent years.

At present, the dry products of lotus root include dehydrated lotus root slices, lotus root powder and fried lotus root crisp slices, which are dried for about 8 hours by blast at 50-55 C. The technological process of producing lotus root powder is material selection, cleaning, grinding, pulping, bleaching, drying and packaging, and the technological process of fried lotus root crisp slices is from fresh lotus root to decoupling. Save, wash lotus root steam lotus root cooling and drying vacuum seasoning low temperature vacuum frying centrifugal deoiling packaging finished products.

Natural drying and hot air drying are time-consuming and the quality of products is poor; low-temperature frying drying is the main processing technology for producing fruit and vegetable crisps, but its products have high oil content and can not adapt to the modern consumption concept of low oil and low fat. Vacuum microwave drying technology and airflow puffing drying technology are two new drying technologies, which have been more and more widely used in the field of dry products processing. Vacuum microwave drying technology has the advantages of energy saving, high efficiency, sterilization and quality assurance. Airflow puffing drying is obtained under the condition of no oil by using the principle of gas hot pressing effect. Loose porous, crisp, green natural products.

But vacuum microwave drying has the disadvantage of uneven heating and easy scorching, and it needs pre-drying before airflow puffing drying to get high quality products. Therefore, according to the characteristics of materials, two or more drying methods are complementary to each other, and combined drying is carried out in stages.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply