- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying characteristics and kinetic model of bitter gourd

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying characteristics and kinetic model of bitter gourd

2018-11-01 13:35:09Abstract: The effects of slice thickness, microwave power and loading on the microwave drying characteristics of bitter gourd were studied by single factor test. The microwave drying kinetics model of bitter gourd was established.

The results showed that the microwave power had the greatest influence on the drying of bitter gourd, followed by the loading, and finally the slice thickness. The microwave drying of bitter gourd accelerated the drying stage and slowed down the drying stage. The fitting of 7 commonly used thin layer drying dynamics mathematical models is obtained by comparing the correlation coefficient R2, the square of the residue and the RSS and the chi square χ2. The tian model is most suitable for describing the microwave thin layer drying process of bitter gourd slices. Above 0.99.

Key words: thin layer drying; microwave drying; drying characteristics; bitter gourd; kinetic model bitter gourd,

Cucurbitaceae Momordica, in addition to water, protein, fat, carbohydrates, crude fiber and various vitamins, bitter gourd also contains bitter gourd, protein-like active substances and a variety of amino acids and a variety of essential mineral elements, with heat Detoxification, nourishing blood and replenishing qi, replenishing the kidney and protecting the spleen, nourishing the liver and clearing the effect, is a therapeutic treatment for diseases such as fire, fever, dysentery and swollen sores in summer. Fresh bitter gourd has a water content of more than 90%, which is not easy to store at room temperature. Drying of bitter gourd is one of the main means of processing and storing bitter gourd fresh products.

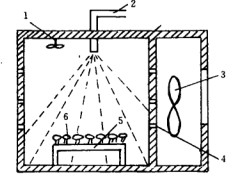

At present, the techniques for drying bitter gourd mainly include hot air drying, microwave drying, heat pump drying, hot air combined with microwave drying, vacuum microwave drying, freeze drying, far infrared drying, and spray drying. The microwave drying equipment is a drying technology with energy saving, uniform drying, high drying efficiency, clean production and high product quality. At home and abroad, there has been research on microwave drying very early. At present, microwave drying technology has been widely used in the field of drying of agricultural products such as fruits, sweet potatoes, vegetables and tea.

Currently bitter gourd microwave drying mainly focused on the optimization of drying process and the study of drying quality, the research on the construction of drying kinetic model has not been reported. Therefore, this paper uses microwave technology to study the heat and mass transfer characteristics of bitter gourd, explore the movement law of water in bitter gourd, and establish the kinetic model of thin layer microwave drying of bitter gourd, to improve the drying process of bitter gourd, improve drying quality and improve drying. It lays a foundation for efficiency and reducing drying energy consumption, in order to provide a theoretical basis for the thin layer microwave drying process and production control of bitter gourd.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply