- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Research status of microwave drying technology for fruits and vegetables at home and abroad

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Research status of microwave drying technology for fruits and vegetables at home and abroad

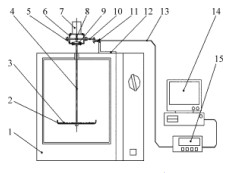

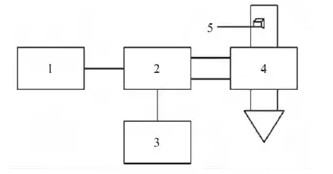

2018-11-02 15:02:43Comparison between microwave drying equipment and other drying equipment

Compared with other drying methods, the microwave drying method of fruits and vegetables has great advantages, which mainly embodies in the maintenance of appearance, micro-structure and nutrients of fruits and vegetables. Khraisheh et al. studied the drying of potato chips by microwave and hot air convection respectively, and observed the changes of quality and texture structure of potatoes.

It was found that the content of vitamin C in potato chips dried by microwave was twice as high as that dried by hot air convection. There is a linear relationship between the shrinkage coefficient of potato volume and the reduction coefficient of water content. The slope of the curve between them remains unchanged during convective hot air drying. That is to say, the volume of potato chips shrinks uniformly with the decrease of water content.

Under microwave drying, the relationship between volume shrinkage coefficient and water content reduction coefficient of potatoes is divided into two straight lines. The slope of the front section is smaller, that is, with the decrease of water content, the volume shrinks slowly, while the slope of the latter section is larger, indicating that with the decrease of water content, the volume of potatoes shrinks rapidly. In addition, it was found that microwave-dried potato chips had better rehydration than hot-air convection-dried potato chips.

The vacuum microwave drying, hot air drying and freeze-drying of carrot slices were studied. It was found that the carrot slices obtained by vacuum microwave drying had higher rehydration and alpha-carrot than those obtained by other drying methods.

Vitamin C is high in content, small in density, soft in texture and good in appearance and color. However, the color of carrot slices obtained by hot air drying is darker. Although the rehydration and nutrient content of freeze-dried products are well maintained, vacuum microwave drying products are slightly superior in color, texture, flavor and overall sensory quality, whether before or after rehydration. In addition, microwave-dried carrot chips have the potential to be used as leisure snacks because of their unique fluffy texture.

The effects of drying conditions on the color, starch content, sugar content, mechanical properties and microstructures of dried potato patches were studied. The results show that microwave vacuum drying can effectively prevent the damage of color in the drying process; the loss of starch and total sugar in potato pellets is lower than that in other methods after vacuum microwave drying; the energy consumption needed to make potato pellets deform 3-5.5 mm is the lowest by microwave drying, but by blanching. Drift and hot air (70 degrees) dry the highest.

Statistical analysis shows that the difference between microwave vacuum drying and hot air convection drying is significant for the maximum pressure value obtained by pressure test. Compared with the products dried by hot air, the micro-structure of the products dried by microwave has different physical changes, and the degree of change depends on the drying method. Under the two drying methods, the cell wall and starch granule structure were deformed and disintegrated. For hot air drying, the change intensity of potato micro-structure mainly depended on the drying temperature, and high temperature would destroy the micro-structure of potato. Hu Qingguo and others used vacuum microwave drying, freeze drying, hot air drying and combined vacuum microwave drying to dry quick-frozen soybean kernels. Their drying effects were compared with the quality parameters of vitamin C and chlorophyll content, color difference, shrinkage and rehydration performance.

The results showed that the retention rate of vitamin C and chlorophyll in freeze-dried fruits and vegetables was the highest in several drying methods, and the color was close to fresh samples, but its shortcomings were that the operation time was too long and the cost was too high; while hot air drying caused the decrease of vitamin C and chlorophyll in fruits and vegetables due to the factors of high temperature, long drying time and easy oxidation. The content loss and color change of freeze-dried fruits and vegetables are not only the greatest, but also the greatest.

The quality parameters of vacuum microwave drying and combined drying with hot air are different from those of freeze-dried products, but they are much better than those of conventional hot air drying, and the drying time can be greatly shortened. The rehydration of freeze-dried fruits and vegetables is much higher than that of other drying methods. However, the texture is too soft and the taste is not good; hot air drying products are tough and hard, and the taste is poor; while vacuum microwave drying or combined drying of hot air and vacuum microwave overcome these shortcomings. Through the above introduction, we can find that microwave drying method has obvious advantages over other drying methods, which is mainly related to its drying mechanism, and is worthy of praise as a fruit and vegetable drying method.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply