- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on pumpkin powder produced by microwave drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on pumpkin powder produced by microwave drying

2018-11-07 16:15:35ABSTRACT: The effects of microwave power, treatment time and slice thickness on pumpkin powder were studied, and their effects on pumpkin powder were compared.

The results showed that the stronger the microwave power was, the faster the water loss rate was, and the shorter the drying time was. The changes of microwave power and microwave treatment time had significant effects on the damage of pumpkin and carotene, while the thickness of pumpkin slices had no significant effect on the damage of pumpkin and carotene.

Pumpkin powder with good quality can be produced by using sliced pumpkin slices with thickness, microwave drying equipment of power and treatment time, and microwave drying method of grinding and sieving to produce pumpkin powder.

Keywords: microwave drying pumpkin powder

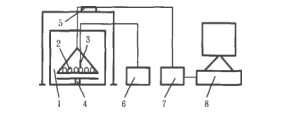

Pumpkin powder is a kind of safe and hygienic modern nutritional and health food because of its rich nutrition, medicinal value and health function. However, the hot air drying method used in pumpkin drying consumes a lot of power, and the loss of nutrients, such as carotene, is also more. Microwave drying mainly uses polar molecules in the medium to vibrate in the electromagnetic field to generate friction heat, and the field energy is transformed into heat energy, so as to achieve the purpose of drying.

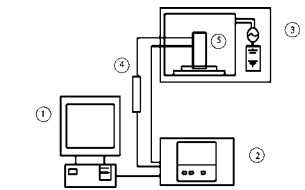

Microwave drying has the characteristics of uniform heating, fast drying speed and automatic heat balance in heating process. It overcomes the shortcomings of conventional drying materials such as uneven heating, large energy consumption, long time and unsatisfactory drying effect. Using microwave technology to dry agricultural products is one of the developing trends in the future. In order to provide theoretical basis for industrialized production of pumpkin powder by microwave drying, the related problems of pumpkin powder production by microwave drying were studied in this paper.

The time of microwave drying is shorter than that of hot air drying. The stronger the microwave power, the shorter the drying time. In the early stage of drying, the stronger the microwave power, the faster the loss of water.

The microwave drying rate of pumpkin slices did not appear a typical constant drying period, but showed a change rule of first rising and then falling, the acceleration period was relatively short; the lower the microwave power, the acceleration period was prolonged, but the whole drying process was basically in a deceleration period.

The changes of microwave power and microwave treatment time had significant effects on the damage of pumpkin 78 and carotene, but the thickness of pumpkin slices had no significant effect on the damage of pumpkin 78 and carotene. The order of influence of three factors was microwave power, treatment time and thickness of pumpkin slices.

It is feasible to produce pumpkin powder by microwave drying with slice thickness, power and treatment time.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply