- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave intermittent drying process of horseshoe starch

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave intermittent drying process of horseshoe starch

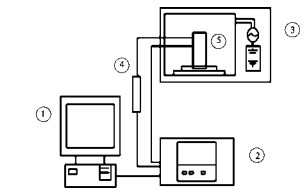

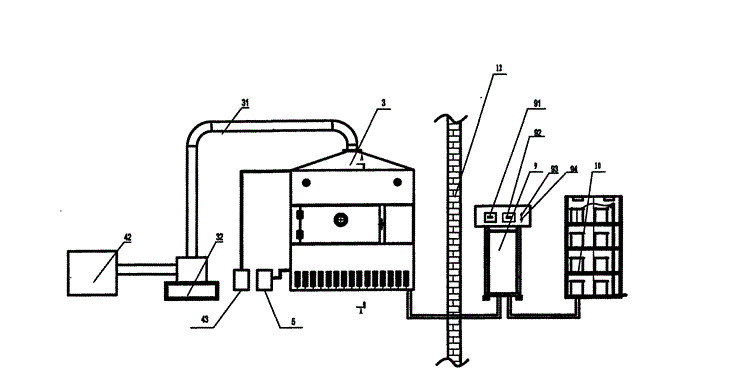

2018-11-08 11:18:12Absrtact: Using horseshoe as raw material, microwave drying equipment was used to drying horseshoe starch. The effects of microwave drying equipment on water content, whiteness, acidity, iodine blue value and comprehensive quality of horseshoe starch were investigated, and the drying process was optimized by orthogonal test.

The results showed that the optimum microwave drying conditions were as follows: microwave power 210W, loading 1.47kg/m2, heating time 14min and intermittent time 0.75min. Under the optimum conditions, the moisture content, whiteness, acidity and iodine blue value of horseshoe starch were 10.12%, 97.5%, 0.21 mL and 17.90 respectively after microwave intermittent drying. After microwave intermittent drying, the moisture content of starch reached the standard of safe moisture content, whiteness was slightly improved, acidity was decreased, iodine blue value was increased, and comprehensive quality was improved.

Keywords: microwave drying of horseshoe starch

Waterchestnut, also known as water chestnut, chestnut, Tongtiancao, is a light-water perennial herb of the family Cyperaceae. Its bulb is flat and round, its skin is chestnut or red-brown after ripening, its surface is bright and delicate, and its flesh is white.

Horseshoe can be divided into fruit horseshoe and powder horseshoe. Among them, powder horseshoe has fine stem and small fruit, rough flesh and many residues. The dry weight of starch, oligosaccharide and monosaccharide accounts for more than 86%. Starch made from powdered horseshoe can be used as an important raw material and auxiliary material in food processing industry. It has great resource advantages and optimistic development prospects.

Evaluating the quality of starchy foods can be reflected by important indicators such as iodine blue value, acidity and whiteness. In the process of horseshoe starch processing, browning and coking phenomena occur from time to time. In order to make the product quality meet the industry standards, advanced processing technology must be adopted.

Microwave drying technology is more and more widely used in agricultural products processing and food industry. In recent two years, there have been related studies on microwave drying of pine pollen, chestnut starch and other powders at home and abroad, but microwave intermittent drying has not been studied and applied in horseshoe starch processing.

In this study, microwave power, loading, heating time and intermittent time were used as the main factors to determine the optimal microwave intermittent drying technology of horseshoe starch, in order to provide theoretical basis for the research of microwave drying of starch.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply