- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Combined drying characteristics of hot air and microwave in corn

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Combined drying characteristics of hot air and microwave in corn

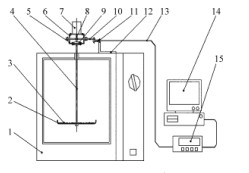

2018-11-08 14:03:50Abstract: In order to explore the efficient drying method of corn large-scale grain varieties, the experimental study on the combined drying characteristics of hot air and microwave was carried out on corn.

In the early stage, it was dried by hot air at 60 °C. When the moisture content of corn was 20%, it was dried by 119 W microwave in the later stage until the moisture of corn was 12%~14%. The change law of moisture and temperature of corn with joint drying time was studied to establish corresponding mathematics. model. Compared to individual hot air drying, the total energy consumption of microwave drying equipment is reduced by 50.6%. The mold counts of different drying methods of corn, the results show that the microwave has obvious bactericidal effect on corn mold.

Key words: food processing technology; corn microwave drying; hot air drying; combined drying; drying model

Dry processing of corn is an important part of safe corn storage. Over the years, domestic and foreign scholars have conducted in-depth research on corn drying technology and equipment, and established corresponding drying theories and models. Microwave drying has the advantages of fast drying efficiency, easy control and sterilization, and has become one of the current development directions of drying technology. The combined drying technology combined with hot air drying technology is modern. One of the research hotspots of drying technology.

At present, there are many reports on the combination of hot air and microwave drying of agricultural products and fish, and there are few researches on hot air and microwave combined drying of corn and other cereals. In this paper, the characteristics and energy consumption of hot air and microwave combined dry corn are studied, which provides a theoretical basis for exploring the development of high quality, high efficiency, energy saving and environmental protection grain joint drying technology and supporting equipment.

in conclusion

(1) The co-drying experiment of hot air and microwave on corn, the drying rate curve shows that the combined drying process is divided into five stages of adjustment, deceleration, adjustment, constant speed and deceleration, and the rate of microwave drying is higher in the later stage. Significantly improved the dehydration efficiency of corn.

(2) A joint drying model of corn hot air and microwave was established. The Page model MR = exp(-k'tn) is suitable for describing the early stage of corn joint drying. The correlation coefficient R2 is the average.

0.9941; single-diffusion model MR = ae-kt is suitable for describing the later stages of joint drying with a correlation coefficient R2 of 0.9978.

(3) The total energy consumption of hot air and microwave combined drying is reduced by 50.6% compared with the energy consumption of hot air drying alone.

(4) The number of molds decreased significantly after microwave drying, and the effect of microwave sterilization was significantly better than hot air drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply