- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimization of microwave drying conditions for kiwi fruit slices

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimization of microwave drying conditions for kiwi fruit slices

2018-11-13 14:23:24

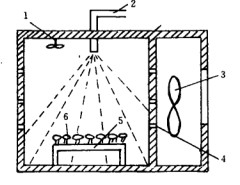

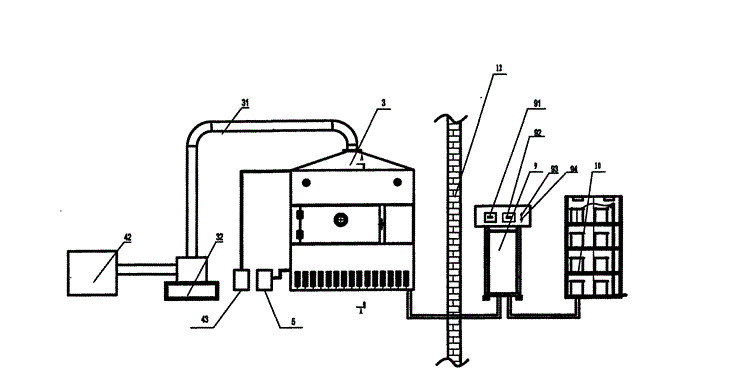

Abstract: The drying curve of kiwi fruit slices after sugar staining under different microwave intensities was analyzed. By designing the regression orthogonal test, the heating temperature, slice thickness and heating time were taken as three factors, and the water loss rate, appearance quality and Vc content were used as the three indexes. The optimization conditions of the kiwi fruit slice microwave drying equipment were proposed: the slice thickness was 9 mm. When the drying time is 104.5 s and the drying temperature is 65 °C, the comprehensive index is the best, indicating that microwave drying has obvious advantages in these aspects.

Key words: microwave drying kiwi fruit slice; drying curve; regression orthogonal test

Microwave heating drying changes the direction of some migration potential and migration potential gradient during the conventional heating and drying process, and improves the moisture migration conditions during the drying process, which is superior to conventional drying. Kiwifruit has high nutritional and economic value and is rich in various nutrients such as sugar, acid, vitamins, protein, minerals and amino acids. Its most prominent feature is the rich Vc content in the fruit, which is known as “fruit. king".

In this study, the advantages and characteristics of microwave drying were used to verify the drying conditions, appearance quality and Vc loss in the production of kiwi fruit slices by microwave drying, and to optimize the processing conditions in the processing of microwave dried fruit slices.

in conclusion

1) By analyzing the microwave drying curve, it shows that microwave drying has the advantages of rapid heating, high efficiency, less nutrient damage and energy saving.

2) The effects of various factors on drying rate, appearance quality and Vc content were analyzed by microwave drying quadratic regression orthogonal test and optimization scheme was proposed: slice thickness was 9 mm, drying time was 104.5 s, and drying temperature was 65 °C. The comprehensive index is optimal, but the moisture content of the fruit pieces in the late dry period is not uniform, the water center is low, and the surrounding area is high.

3) Although microwave drying has many advantages, due to the complexity and transient nature of the microwave heat transfer process, a theoretical model that reasonably describes its process characteristics needs further research.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply