- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Formulation and Drying Process of Reshaped Composite Fruit and Vegetable Chips

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Formulation and Drying Process of Reshaped Composite Fruit and Vegetable Chips

2018-11-16 13:46:03

Abstract: Using pumpkin, carrot and pear as the main raw materials, we developed a reshaped composite fruit and vegetable nutrition chip suitable for children. The microwave drying equipment, comprehensive test and orthogonal test were used to optimize the formula and process of the chips. The results showed that the best mass ratio of pumpkin pulp, carrot pulp and pear pulp was 3:3:2, and 100 g of compound fruits and vegetables.

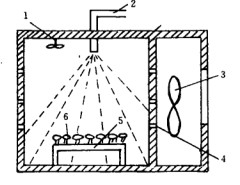

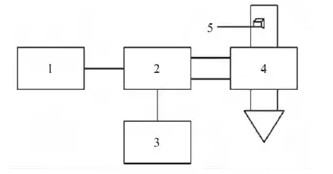

Based on the pulp, the optimum amount of excipients is 75 g of flour, 13 g of butter, 12 g of white sugar, and 1.0 g of salt. Compared with microwave drying, far-infrared drying and far-infrared-microwave combined drying, it is considered that far-infrared drying is the best. The optimum process conditions are ignition temperature 170 °C, ignition temperature 130 °C, and time 15 min. The composite fruit and vegetable chips prepared under the conditions have good sensory qualities.

Key words: vegetable and vegetable chips microwave drying; formula; far infrared drying; far infrared-microwave combined drying

As the “fourth meal” in the daily life of the people, snack food is developing in the direction of health, nutrition and safety. Children are the future of the motherland, and the quality and safety of children's snack foods are closely related to their healthy growth. Fruit and vegetable chips are a kind of healthy, nutritious and delicious food in snack foods. However, currently, commercial products generally use single fruits and vegetables as raw materials, and there are problems that nutrients are not rich and balanced. In addition, many vegetable chips are fried and dehydrated. Made of oil, the oil content is relatively high, easy to produce toxic and harmful substances such as acrylamide, long-term consumption, is not good for the healthy growth of children.

Pumpkin, rich in pumpkin polysaccharide, pectin, β-carotene, vitamin C [3-4] and mineral elements such as potassium, calcium and magnesium, compared with other melons and vegetables, β-carotene, zinc, chromium , manganese and other content is higher. The above nutrients can improve the body's immunity, protect vision, promote epithelial cell growth and differentiation, promote bone development, reduce the risk of cancer in children, reduce blood lipids, and promote the metabolism of sugars and proteins [5]. Pear, crispy and juicy, sweet and delicious, rich in carbohydrates, vitamins, minerals and polyphenols, can relieve cough and lungs, improve children's respiratory and lung function.

Carrot, known as the underground "small ginseng", is rich in polysaccharides, β-carotene, vitamin C and other nutrient functional ingredients, especially the high content of dietary fiber such as pectin. It is a common nutritious food with lower price. Raw materials, but the nutrients such as raw carrots β-carotene are not fully absorbed, and because the main flavor substances are terpenoids, cooking taste is easy to occur at high temperatures, which causes many children not to like the flavor of cooked carrots, which limits the processing of carrots in children's food. In the application. Pumpkin, pear and carrot are the main raw materials, supplemented by natural flavor materials, and made into compound fruit and vegetable nutrition chips, which can achieve multiple optimization and complementation of nutrition, flavor and economic benefits.

Drying is a common means of preserving fruits and vegetables. By removing water from fruits and vegetables, it can effectively inhibit microbial activity and enzyme activity of fruits and vegetables, so that the shelf life of fruits and vegetables can be prolonged. Common fruit and vegetable drying techniques include hot air drying, infrared drying, vacuum frying, and microwave drying. , vacuum drying, vacuum freeze drying, pressure difference puffing and drying. Puffing refers to the use of frying, extrusion, sand frying, baking, microwave and other techniques as a curing process. After the maturation process, the product volume is significantly increased, and the technology has a certain degree of crispness. Fruit and vegetable chips should not only pursue a long shelf life, but also have a crisp taste. Therefore, while drying, it must produce a puffing effect. Microwave and infrared heating technology can not only dehydrate and dry, but also produce fruits and vegetables. Crisp taste.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply