- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on High Power Microwave Drying Process of Plate Pepper

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on High Power Microwave Drying Process of Plate Pepper

2018-11-29 15:44:44

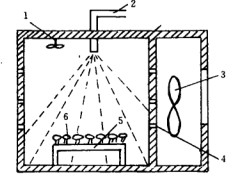

Abstract: The orthogonal test of plate pepper microwave drying equipment was carried out with the water loss rate of plate pepper and the drying quality of plate pepper as the evaluation index. The effect of microwave drying process parameters on the drying quality of pepper was obtained. The optimum process parameters are: microwave power of 4000W, drying time of 20min, plate pepper treatment method for hole piercing on the surface of the pepper, microwave working mode is 180s/180s intermittent heating mode.

Key words: plate pepper microwave drying; high power; orthogonal test

Capsicum has a high pigment content and can be used as an industrial raw material to extract natural pigments. It has a certain position in agricultural products and has a broad market prospect. Pepper is widely cultivated in China, and it is widely planted in the south and north. At present, the degree of mechanization of pepper drying in China is very low, mainly due to natural sun drying. The reason is that there is no efficient and low-cost pepper industrial drying machine.

Natural drying has a long drying time, large labor, poor sanitary conditions, easy mold growth, high product loss, and limited by weather and site. Therefore, it is expected that a compact device with simple structure, simple operation, automation, continuous, low input, high output, low energy consumption and excellent quality can be designed and developed. Microwave drying has its own unique advantages, high drying energy conversion efficiency, sterilization, easy automation, and continuous. However, there are few studies on high-power microwave drying of fruits and vegetables.

He Mingxi and other studies have shown that the water content of fruits and vegetables is more than 80%, the time of moisture escape during drying takes time, and the heating temperature can not be higher than 80 °C, so as not to cause "cooking" phenomenon; In addition, when the material is placed in a single layer, microwave heating The efficiency is not high, and the stacking is hindered by moisture escaping, and the “cooking” phenomenon is more likely to occur in the middle of the stacking area. Therefore, high-power microwave equipment is not suitable for the drying of fruits and vegetables from the aspects of equipment investment, processing cost and quality of processed products.

However, this paper believes that the use of high-power microwave drying of fruits and vegetables, as long as the rational design of the drying process, so that it is stacked with a reasonable thickness, control the drying process temperature is less than 70 ° C, so that it does not occur "cooking" phenomenon, and maximize the efficiency of microwave work It is possible to dry fruits and vegetables with high-power microwaves.

In this paper, the effect of high-power microwave on the drying quality of pepper was studied under different drying processes, in order to find a process that can ensure the drying quality and efficiency of the pepper, and provide a basis for the design and research of industrial drying equipment.

It is known that the higher the microwave power, the higher the water loss efficiency, but it is easy to cause the boiling or smearing of the pepper, and reduce the drying quality of the pepper. The longer the microwave drying time, the more the water loss rate, but the efficiency is low.

The microwave intermittent heating method is to stop the microwave heating during the high-power microwave drying process, stop the microwave heating, and then turn on the microwave heating, which is beneficial to ensure the quality of the plate drying and improve the drying. effectiveness. The method of puncturing or cutting the surface of the pepper has no effect on the drying quality of the pepper, but it is beneficial to increase the water loss rate of the pepper, thereby improving the drying efficiency, and the surface puncturing method is simpler than the cutting method.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply