- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on the effect of drying methods on fresh-keeping and quality of semi-dry noodles

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on the effect of drying methods on fresh-keeping and quality of semi-dry noodles

2018-12-28 10:17:58

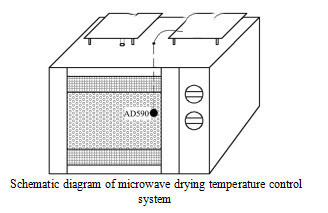

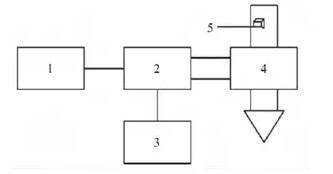

Absrtact: Ultraviolet-microwave drying and electrothermal drying were used to dry fresh and wet noodles. The effects of microwave drying equipment on the microbial content and quality of semi-dry noodles were compared and analyzed.

The results showed that the electrothermal drying efficiency was low, and the sterilization effect was not obvious at the later stage of drying; the ultraviolet-microwave drying efficiency was high, and the bacterial content of noodles continued to decline at the later stage of drying. Both drying methods could significantly reduce the initial bacterial content of semi-dry noodles.

For electrothermal drying, the total number of bacteria in semi-dry noodles decreased significantly at 125 C, which had little effect on texture and cooking quality. For ultraviolet-microwave drying, the initial bacterial content of semi-dry noodles was significantly lower than that of electrothermal drying at different power levels. When the microwave power was 2 000 W, the quality of semi-dry noodles was better, which was the more suitable microwave drying power.

Key words: semi-dry surface microwave drying; electrothermal drying; ultraviolet-microwave drying; bacterial content; texture; cooking quality

Semi-dry noodles are a new type of instant noodles developed in recent years. They are noodles made from wheat flour through mixing, ripening, calendering, slicing, partial dehydration, even wetting and packaging. Their moisture content keeps between 20% and 25%. They are popular with consumers because of their advantages of convenient cooking, strong noodle flavor, chewing strength and healthy nutrition.

However, the mild processing technology of semi-dry noodles and the high moisture content of noodles cause the problems of rapid growth and reproduction of microorganisms and short shelf life during storage. Drying is a very important link in the production of semi-dry noodles. It is also an effective measure to effectively reduce the bacterial content of semi-dry noodles and to prolong the shelf life of semi-dry noodles.

At present, the main method of dehydration for Semi-dry surface is electrothermal drying, but it has some shortcomings such as high energy consumption and large floor area. Ultraviolet-microwave drying is a new method of dehydration and sterilization. It is an indispensable means for food cleaning processing and production to combine ultraviolet and microwave to sterilize materials while using microwave to dry them.

The drying characteristics and bacteriostasis of wet noodles under ultraviolet-microwave drying and electrothermal drying were studied. The effects of different drying conditions on the initial bacterial content, texture and cooking characteristics of semi-dry noodles were compared. The aim was to provide theoretical basis for the optimization of industrial drying technology of semi-dry noodles and provide technical support for industrial operation.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply