- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Drying Model of Apple under Controlled Dehumidification Pressure

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Drying Model of Apple under Controlled Dehumidification Pressure

2019-01-08 13:17:32Absrtact: The influence of dehumidification pressure on the water ratio of drying was studied by using a constant temperature microwave drying device. Non-linear fitting of test data for 8-minute thin-layer drying model of food was carried out. The determination coefficients R2, chi-square 2 and standard error E were compared and evaluated, as well as the validation test.

The results showed that Page model was the best model to describe the process of Apple microwave drying equipment. Deff is used to solve the effective water diffusion coefficient under different drainage pressure. Deff increases with the increase of drainage pressure. The research on microwave drying process model of apple under different dehumidification pressure provides a theoretical basis for Apple drying production.

Key words: Apple microwave drying; drying characteristics; thin layer drying model

Drying is a complex process of heat and mass transfer. Food drying becomes more complex because of the difference of material structure. In industrial applications, drying equipment for food is more complex than that for water removal only, so more effective models are needed for process design, parameter optimization, energy integration and process control. Although the research of model is very important in food drying, there is no theoretical model which can be widely used in practice and unified expression. Therefore, the experimental study in drying process is particularly necessary in establishing the model. The thin layer drying model of the mathematical model of food drying is based on the liquid phase diffusion theory, and has been well verified in practice.

TLC drying model can be generally divided into theoretical equation, semi-empirical equation and empirical equation. Semi-empirical equation is widely used because of its high fitting degree and small error. Akpinar selected 13 thin-layer drying models to study fruits and vegetables including apples. The Midilli-Kucuk model was the most suitable one for hot-air drying. Menges et al. selected 14 drying models to study the hot air drying characteristics of apples under different temperatures and wind speeds. The Midilli model was considered to be the most suitable one for describing the change of water ratio of apples in the range of 60-80 C and 1.0-3.0 m/s.

Sacilik et al. studied the drying characteristics and drying models of 5-9 mm organic apple slices at 40, 50 and 60 C. The Logarithmic model was the best among the 10 models. Guan Zhiqiang et al. used nine models to non-linear fit the drying test data of litchi pulp under different hot air temperature and wind speed. By comparing the test indexes and test verification, it showed that Page model was the best model to describe the drying process of litchi pulp thin layer by hot air. Li Hui and others studied the characteristics of vacuum microwave drying of litchi pulp. Nonlinear regression fitting was used to solve 12 drying models and the model coefficients were determined. The results showed that Modified Henderson and Pabis model could more accurately express and predict the law of moisture change in the process of microwave vacuum drying of litchi pulp.

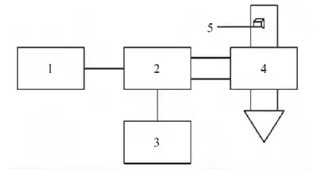

A large number of studies at home and abroad focus on the effects of different temperature, power and other parameters in the drying process. Few studies have been reported on the characteristics and models of microwave drying process under different dehumidification pressures. In this study, a constant temperature microwave drying system was used to study the effect of dehumidification pressure on Apple drying characteristics, and a microwave drying dynamic model was established to clarify the law of Apple microwave drying and provide scientific basis for industrial application.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply