- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Current situation and technical optimization of walnut drying in Xinjiang

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Current situation and technical optimization of walnut drying in Xinjiang

2019-01-08 15:05:38

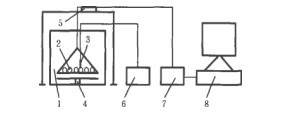

Absrtact: Drying plays an important role in the Postharvest processing, storage and transportation of walnuts. In this paper, the current situation and existing problems of microwave drying equipment for walnut in Xinjiang were described in detail, and the corresponding technical analysis and optimization were put forward. According to the main walnut varieties in our region, combined with local environment and hot air drying as the main method, the combined drying technology combined with various drying technologies was one of the main research directions in the future.

Key words: walnut microwave drying; drying technology; research status; technology optimization

Walnut, also known as walnut, is one of the four dried fruits in the world. It is also an important part of China's forest and fruit production. As a major walnut producer, China ranks first in the world in planting area and yield. The main cultivation areas of Walnut in China are Yungui, Northwest and North China. Xinjiang is one of the main walnut production areas, many counties and towns have walnut distribution.

Xinjiang, especially in southern Xinjiang, has long illumination time, high effective accumulated temperature, large temperature difference between day and night, less rainfall in growing season and dry air, which is not only conducive to fruit ripening, but also inhibits the growth of pests and diseases. It also has suitable climate conditions for walnut growth and development, good ventilated and permeable soil and complete irrigation and water supply facilities, as well as the industrial policy of developing walnut. The unique advantages of development.

The walnut producing areas in Xinjiang mainly distribute in Aksu area, Hetian area and Kashgar area. In recent years, with the improvement of technological level, the annual yield of Walnut in Xinjiang has greatly increased. However, because of the concentrated harvest time, fresh walnuts after harvest can not be treated in time, and often produce mildew, which brings great economic losses to farmers. The drying treatment of walnut is one of the important links in the post-harvest processing of walnut fruit, and it is very important to preserve the nutrition, color and follow-up value of walnut. .

Walnut drying process is accompanied by a large amount of energy consumption and high human and material costs, so how to choose the appropriate walnut drying process for farmers is a key issue to consider.

Compared with the traditional drying technology, the new drying technology has the characteristics of faster efficiency, better product quality and higher standardization. It can further tap the added value of walnut drying products. However, although the new drying technology greatly improves drying efficiency and reduces human consumption, the application of high-tech has brought more energy consumption and demand than traditional drying technology. How to consider the balance between energy consumption, manpower consumption, production cost, drying rate and drying quality is a problem worth pondering.

There is a great contradiction between the economic benefits of drying and the quality of products. How to reduce the cost of drying technology and obtain high-efficiency and high-quality walnut products has always been the core issue of walnut drying technology. Compared with the high cost and difficulty of developing a new type of high efficiency, energy saving and high quality drying technology, the combined drying technology has great advantages in research and development cost, research and development difficulty and production application.

At present, the combined drying technology in our country is mostly focused on the process research, most of the research is still in the laboratory stage, the data obtained can not be directly applied to production practice, it is difficult to achieve industrial development.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply