- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying on the quality of burdock chips

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying on the quality of burdock chips

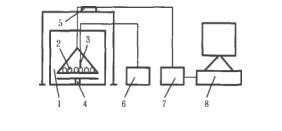

2019-01-09 15:46:23Abstract: The effects of hot air, microwave drying equipment, vacuum freezing, hot air combined with vacuum microwave and vacuum freezing combined with vacuum microwave on drying time, color, shrinkage, microstructure, polyphenol content, flavone content and polysaccharide content of burdock chips were studied.

The results showed that the product had large color difference, severe shrinkage and more nutrient loss after drying by hot air, vacuum microwave and hot air combined with vacuum microwave, and the quality of the product was significantly lower than that of other drying methods. The quality of vacuum freezing combined with vacuum microwave drying is close to that of vacuum freezing drying. The porous structure inside makes the product have moderate hardness and brittleness. The contents of polyphenols, flavones and polysaccharides are well retained, while the drying time is shortened by 46%. In conclusion, vacuum freezing combined with vacuum microwave drying is the most suitable processing method for burdock chips.

Key words: burdock microwave drying; chips; production technology; drying methods; physical indicators; nutritional indicators; quality; drying time; microstructure

Arctium lappa L. is a 2-year-old herb of Arctium lappa L. in Compositae. Arctium lappa is rich in nutrition, which contains polyphenols with strong antioxidant, anti-bacterial, anti-inflammatory, anti-mutation, blood pressure and other effects; Arctium lappa polysaccharides can promote the proliferation of lactic acid bacteria and bifidobacteria in vivo, maintain intestinal microecology. Burdock is mainly planted in Shandong, Jiangsu, Anhui, Heilongjiang and other provinces. Export is the main selling mode. However, with the in-depth study of burdock nutrition, its edible value and medicinal value have been paid more and more attention in China.

The flesh of fresh burdock root is gray and white, which contains a lot of fibers. It is easy to fibrosis and become hollow in the later growth period and storage process. After burdock root fibrosis, the content of cellulose and lignin increased rapidly, resulting in further hardening of the structure, which not only affects the taste of food, but also brings difficulties for further processing. At present, burdock dry products mainly include burdock tea and burdock crisps. Burdock chips are usually fried in vacuum, which results in serious nutritional loss and easy oxidation of oil. Long-term consumption of burdock chips can easily lead to health problems.

Non-frying drying mainly includes hot air drying, microwave drying, far-infrared drying, freeze-drying, combined drying and so on. Paengkanya et al. found that the drying rate of durian by vacuum microwave combined with hot air drying was faster than that by single vacuum microwave and hot air drying, and the brightness and brittleness of durian products could be increased, and the shrinkage and hardness of durian products could be reduced. Chong et al. found that convection combined vacuum microwave drying can save 50% of drying time, while heat pump combined vacuum microwave drying can produce apples with small shrinkage rate, small color change, the highest polyphenol retention rate and the strongest antioxidant activity. In these two combined drying methods, the application of vacuum microwave greatly reduces the hardness and brittleness of products, and makes the taste better.

The above research shows that combined drying can effectively improve drying efficiency and product quality, but due to the fibrous structure of Arctium lappa root, the effect of non-frying drying, especially combined drying, on drying Arctium lappa chips needs further study. In this study, burdock chips were dried by hot air drying, vacuum microwave drying, vacuum freeze drying, hot air combined with vacuum microwave drying and vacuum freeze combined with vacuum microwave drying. The differences of physical and nutritional indexes of burdock chips produced by different drying methods were analyzed, and the effects of different drying methods on the quality of burdock chips were discussed in order to determine the suitable burdock chips. The drying technology of slice production provides theoretical basis and technical support for the comprehensive development and utilization of burdock.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply