- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Combined drying process optimization and dynamic model of Hawthorn hot air and microwave

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Combined drying process optimization and dynamic model of Hawthorn hot air and microwave

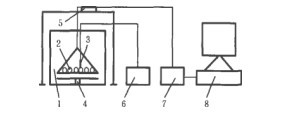

2019-01-10 14:18:27In order to explore the best drying process and the drying process of the product moisture changes of dry hawthorn, hawthorn as raw material, hot air, the microwave drying alone and combined drying. Through the orthogonal test analysis of optimum conditions of combined drying of hawthorn, using 16 kinds of fruit and vegetable slices drying model to fit test data, determine the dynamic model for the combined drying of hawthorn.

The results show that the hot air microwave drying has advantages of hot air and microwave drying alone, the best conditions of drying: air temperature is 75 DEG C, the conversion rate of water content 50%, microwave power density of 2.7 W/g; hot air and microwave drying equipment of Hawthorn combined drying can be used in Approximation of diffusion Hii and model and others model are described. The research results can provide theoretical basis and guidance for the deep processing technology of hawthorn and industrial applications.

Key words: microwave drying of hawthorn;Hot air and microwave drying; orthogonal test; dynamic model

Hawthorn is rich in nutrients, high medical value, known as the "longevity fruit". Because fresh hawthorn is not easy storage, easy oxidation and spoilage, it is currently marketed by hawthorn hawthorn processing products, including dried hawthorn tablets, tablets, hawthorn juice, solid beverage etc..

Among them, the most widely used Hawthorn dry film, can be used to make medicines and other processed products of raw materials. The production of Chinese hawthorn tablets by dry dehydration, but the dehydration process is time-consuming, high energy consumption, therefore, in order to improve production efficiency, reduce cost, obtain high quality dried products, need to improve the existing drying process.

In recent years, in the field of fruit and vegetable dehydration, drying technology has become the new darling of the scholars "". Among the combined drying method, hot air microwave drying is widely used by researchers, because it is very good with the advantages of simple operation, hot air drying and microwave drying time is short, fast speed, and overcomes the hot air drying time is long, high energy consumption, microwave drying unevenness defects. At present, some scholars use hot air and microwave drying technology of dry fruits and vegetables, such as orange peel, pumpkin, spinach, ginger, sliced apple and kiwi.

At present, domestic and foreign to the Hawthorn drying using hot air drying air impingement drying and microwave drying hot air coupling method, studied the Hawthorn hot-air and microwave combined drying research.

Therefore, the use of hot air and microwave drying of hawthorn, explore the optimum conditions to obtain high quality dried Hawthorn slice, and examine the applicability of the existing model to describe the dynamics of fruit and vegetable slices of Hawthorn water changes during drying. This study provides a new method for hawthorn products of industrial production, and provide a theoretical basis for the design and improvement of production equipment of hawthorn products.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply