- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Drying Method on Volatile Flavor Components of Agaricus blazei Murrill

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Drying Method on Volatile Flavor Components of Agaricus blazei Murrill

2019-01-15 13:32:31ABSTRACT: The volatile flavor components of fresh Agaricus blazei Murrill, hot air constant temperature drying, microwave drying equipment and vacuum freeze drying were detected and analyzed by headspace solid phase microextraction (HSSPME) combined with gas chromatography-mass spectrometry (GC-MS).

The results showed that 20, 50, 43 and 22 volatile flavor components were detected in fresh Agaricus blazei Murrill, hot air constant temperature drying, microwave drying and vacuum freeze drying, respectively.

Alcohol, aldehyde, ketone, phenol and ether were newly formed by hot air constant temperature drying, which had certain effect on the improvement and flavor enhancement of Agaricus blazei Murrill. More aldehydes were produced by microwave drying, which made the dried Agaricus blazei Murrill have special cinnamon aroma and bitter almond-like aroma. Vacuum freeze-drying treatment of Agaricus blazei Murrill and fresh Agaricus Murrill had close overall flavor components, indicating that vacuum drying could improve the flavor of Agaricus blazei Murrill. Freeze-drying method can keep the original flavor of Agaricus blazei Murrill better.

Key words: Agaricus blazei Murrill microwave drying; drying method; flavor components; gas chromatography-mass spectrometry

Agaricus blazei Murrill, also known as Brazilian mushroom and small mushroom, is a medicinal and edible fungus originating in the United States and Brazil, which is called "God's mushroom" locally. Agaricus blazei Murrill has a strong almond aroma, rich in polysaccharides, proteins, vitamins and trace elements, and has many health functions that other food resources can not replace.

Fresh Agaricus blazei Murrill is liable to rot and deteriorate because of its strong respiration and high moisture content, so it must be preserved. Dry Agaricus blazei Murrill products are easy to store and transport, and have a long shelf life. Relevant studies have shown that drying method is an important factor affecting the quality of dried food, especially the flavor of the products. The types and contents of volatile flavor components are important indicators affecting the quality of dried food.

In recent years, the extraction of Polysaccharides from Agaricus blazei Murrill, liquid fermentation, functional components and medicinal mechanism have been mainly studied at home and abroad, and the influence of volatile flavor components and comprehensive quality of Agaricus blazei Murrill has been less studied. During the drying process of Agaricus blazei Murrill, due to the evaporation of water and the interaction between molecules, volatile flavor components are prone to change or lose, and new substances are also produced.

The flavor components of fresh Agaricus blazei Murrill and its dried products were analyzed, which not only provided theoretical basis for the selection of drying technology of Agaricus blazei Murrill, but also provided reference for the determination of drying methods of other edible fungi.

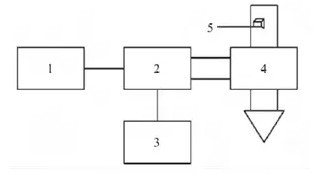

In this study, headspace solid-phase microextraction (HSSPME) combined with gas chromatography-mass spectrometry (GC-MS) was used to qualitatively analyze volatile flavor components in hot air constant temperature drying, microwave drying, vacuum freeze-drying and fresh Agaricus blazei Murrill. The effects of three drying methods on volatile flavor components of Agaricus blazei Murrill were compared in order to provide theoretical basis for the selection of drying methods of Agaricus blazei Murrill and other edible fungi.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply