- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Low Temperature Drying Technology of Selenium-enriched and GABA-enriched Germinated Brown Rice

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Low Temperature Drying Technology of Selenium-enriched and GABA-enriched Germinated Brown Rice

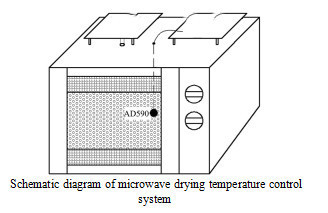

2019-01-22 15:45:27The technology of low temperature drying of germinated brown rice with selenium-rich and gamma-rich argyrophilic butyric acid (GABA) was studied, and the effects of low temperature microwave drying and hot air drying on the edible and nutritional quality of germinated brown rice were discussed.

The results showed that the food quality and nutritional quality of germinated brown rice decreased with the increase of drying temperature, and the lower the temperature of microwave drying equipment, the better the quality of germinated brown rice could be maintained. The browning reaction of germinated brown rice was intensified from 40 C to 60 C, and the color of germinated brown rice was darkened; the hardness and nozzle value of germinated brown rice increased, and the taste became worse; the viscosity of germinated brown rice paste increased, and the quality decreased.

After microwave and hot air drying, the CABA content in germinated brown rice decreased by about 25% and 27%, and the sun content decreased by about 30% and 7%, respectively. Therefore, the optimum drying conditions for hot air drying are 270 min at 45 C and 75 min at 45 C. After drying, the germinated brown rice has high content of sunshine and GABA and good edible quality.

Key words: brown rice microwave drying; low temperature; hot air drying; germination; brown rice quality

Germinated brown rice is obtained by activating related enzymes in brown rice under certain conditions. After germination, brown rice is richer in nutrients. It not only enriches a large amount of Y-aminobutyric acid (CABA), but also softens the bran layer fiber of brown rice, which improves the taste of brown rice. Brown rice has a high moisture content after germination under the existing technological conditions. It needs to be further dried to safe moisture before it can be stored for a long time.

At present, the main drying methods for germinated brown rice are sunlight drying, hot air drying, microwave drying and vacuum freeze drying. The results showed that vacuum freeze drying had the least effect on the quality of germinated brown rice, followed by microwave drying and hot air drying.

On the other hand, the cost of vacuum freeze drying is high, which is not suitable for commercial production; the speed of daylight drying is slow, and it is difficult to control the external environment; hot air drying and microwave drying are two commonly used drying methods, which are widely used and economical, but high temperature drying can also reduce the food quality and nutritional quality of germinated brown rice.

Therefore, this study explored the effects of low-temperature hot air drying and microwave drying on the quality of high GABA germinated brown rice in Fuxi, and developed low-temperature quality preservation drying technology for Germinated Brown rice, which could provide reference for commercial production of germinated brown rice.

In this study, the low temperature drying technology of germinated brown rice and the effects of drying on the edible and nutritional quality of germinated brown rice were studied. The results showed that the food quality and nutritional quality of germinated brown rice decreased with the increase of drying temperature, and the lower the temperature, the better the quality of germinated brown rice was.

The browning reaction intensified and the color of germinated brown rice darkened when the drying temperature increased from 40 ~60 ~C; the hardness and chew value of germinated brown rice increased, and the taste became worse; the viscosity of germinated brown rice paste increased and the quality decreased; the GABA content in germinated brown rice decreased by about 25% and 27% respectively after microwave and hot air drying, and the selenium content decreased by about 30% and 7% respectively. To sum up, from energy saving, time saving and actual production, etc.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply