- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Physical changes and mechanism of litchi fruit pruning during microwave intermittent drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Physical changes and mechanism of litchi fruit pruning during microwave intermittent drying

2019-01-23 14:12:11ABSTRACT: In order to explore the mechanism of heat and mass change of Litchi Fruit during microwave drying and reveal the physical change process of Litchi Fruit during drying.

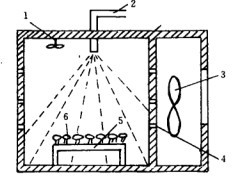

Based on the changes of microwave drying equipment, energy consumption, temperature gradient, browning and pulp shrinkage of litchi, the physical change process from microwave intermittent drying of fresh litchi fruit to semi-dried litchi dried fruit was analyzed. It was proved that microwave intermittent drying technology for whole litchi fruit had the characteristics of fast drying, uniform pulp quality, low energy consumption and simple equipment. Advantages.

The results show that under the conditions of comprehensive energy consumption, color and shrinkage, the optimum heating intermittent time is 7s/65s at 700W microwave output power. The energy consumption is 2.11. The dried litchi presents uniform golden color with L*, a*, b* values of 37.5, 14.4 and 16.4, respectively.

The shrinkage of pulp followed a nearly linear expansion/contraction pattern, and there was no obvious depression on the surface of peel. The experimental study provides a reference for the selection of suitable microwave drying method for semi-dried litchi and the computer simulation model for the change of moisture and temperature of Litchi during microwave drying.

Key words: litchi microwave drying, intermittent drying, physical changes

Litchi is a dominant fruit in southern China. Its fruit body structure is a multi-structure complex, including porous medium shell, flexible body pulp and cork structure core. The thermophysical parameters of each component are very different, and the drying dehydration characteristics are different from those of general porous medium and homogeneous body.

The production of litchi is seasonal and the harvest period is concentrated. The water content of fruit body is more than 80%. A large number of high-moisture litchi need to be dried in time and lack of drying equipment, which leads to the problem of litchi decay and deterioration. Solving the problem of timely and efficient drying of fresh litchi fruit has important social significance and economic value.

At present, some achievements have been made in the research of multi-layer structure drying technology of fresh litchi fruits. Researchers have carried out microwave, hot air, vacuum and heat pump microwave combined drying technology research around semi-dry litchi drying. The characteristic curves of technological parameters of continuous drying and intermittent drying of litchi have been obtained. The Poisson equation, hot air mass transfer equation and fractal model of wet phase of materials have also been studied. The overall contraction law of materials with water content was obtained, but the drying process of litchi fresh fruit layers could not be monitored effectively.

The reason is that litchi is a multi-structure complex. When analyzing the change of fruit drying process, the non-linear change of physical properties of shell, pulp and stone and the law of heat and mass transfer between layers are not taken into account, and the effect of litchi micro-pore structure on the whole fruit is neglected.

In view of this, the microwave intermittent drying technology was used to compare and analyze the quality, color, shrinkage and internal and external temperature changes of granular fresh litchi fruits. The internal physical changes of microwave drying fresh litchi fruits were found.

The mechanism changes of temperature rise and water loss in different stages were analyzed to provide reference for selecting suitable microwave drying methods for semi-dried litchi and studying the computer simulation model of water and temperature change in microwave drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply