- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying characteristics of corn and its effect on quality

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying characteristics of corn and its effect on quality

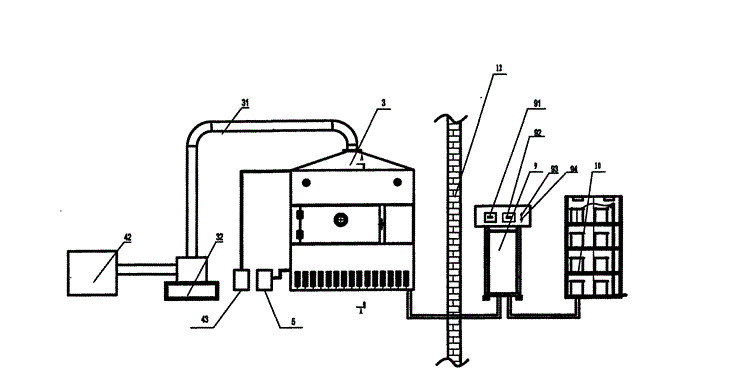

2018-10-17 15:18:34It can be concluded from the diagram that the moisture content of maize decreases slowly, the total drying time increases slightly, and the temperature decreases slightly with the increase of air velocity. When microwave drying equipment is used, because the temperature of corn is higher than the temperature of dehumidification air flow, the convective heat transfer between corn and its surroundings is enhanced and the heat loss for dehydration is relatively reduced with the increase of dehumidification air velocity. However, there is a certain self-modelling zone in microwave drying, which has less influence.

2.2 effect of drying characteristics on quality after drying

2.2.1 The effect of different drying conditions on the germination rate of maize grain is shown in Table 2. Generally speaking, with drying

With the increase of power, temperature and wind speed, the germination rate is decreasing and drying.

The higher the power, temperature and wind speed, the faster the germination rate will drop. Through orthogonal test analysis, it was concluded that the primary and secondary factors affecting maize seed germination rate were B > A > C. Further analysis of variance showed that drying power and temperature had a very significant effect on Maize Seed Germination rate, but wind speed and the interaction between the three factors had no significant effect on Maize Seed Germination rate.

Therefore, considering the maximum germination rate of maize grain, the optimum combination of microwave drying equipment for corn is as follows

A2B 1C2.

(1) Microwave drying is different from conventional hot air drying and other drying methods. Temperature gradient, heat transfer direction and moisture migration direction are the same in the drying process. The overall drying speed is increased and drying time is shortened. The drying rate of materials in the drying process mainly depends on drying power and wind speed.

(2) the microwave drying process of corn is divided into 3 stages: pre drying, constant speed drying and slow drying. The accelerated drying stage is longer. Most of the dehydration processes are in a relatively constant drying stage. In the drying stage, the moisture content gradually slows down. Therefore, microwave drying can be done according to the initial moisture content of corn.

(3) Drying power, drying temperature and drying wind speed are the main technical parameters of microwave drying of maize grain, which directly affect the drying time, quality and energy consumption after drying. The experiment shows that the best drying technology of microwave drying corn kernel is drying power.

0.2 W/g, drying temperature 40 C, wind speed 45 m/min, can ensure the seed, edible value and easy storage of corn after drying, and low energy consumption.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply