- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

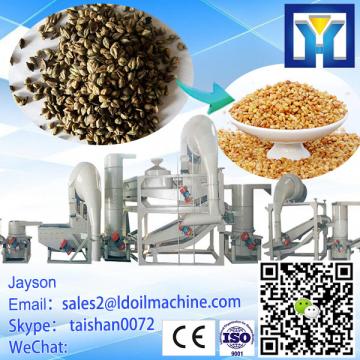

Small size peanut skin removing machine Groundnut shelling machine

Manufacturers of all Tartary buckwheat dehulling and separating equipment are represented in our partial list of clients. Contact Gary for a complete Shandong Microwave Machinery Co.,Ltd. Small size peanut skin removing machine Groundnut shelling machine list of clients and projects.

- Negotiation

- Negotiation

-

Shandong Microwave Machinery Co.,Ltd.2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Shandong Microwave Machinery Co.,Ltd.2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Contact Us

- Shandong Microwave Machinery Co.,Ltd.

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

Related News

| Microwave potato chip machine: Mom no longer has to worry about my health |

| Microwave thawing technology-let you eat healthy and assured meat |

| Before making furniture, why we have to dry and insecticidal wood material? |

Product Categories

- Food Microwave Machine

- Industry Microwave Machine

- Hot Air Dryer Machine

- industrial microwave oven

- industrial microwave dryer

- fruit drying machine

- pasta drinking straws making machine

- spaghetti straws making machine

- weigh filler packaging machine

- automatic weighing and filling machine

- weighing and bagging machine

- industrial belt dryer

- continuous belt dryer

- hot air drying tunnel

- fully automatic potato chips making machine

- fresh potato chips machine

- pet food processing line

- food factory production line

New Products

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply